– 85 –

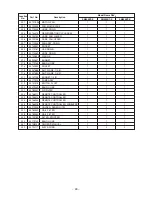

No.

Part name

Procedure

Remarks

1. Detachment

1) Perform works of 1 of

c

.

(In case of under air intake)

Perform works of 1 of

d

.

(In case of back air intake)

Perform works of 1 of

e

.

2) Remove the indoor/outdoor connecting wire and

remote controller wire from each terminal block.

3) Remove the connectors which connected

from the control P.C. board to other parts.

NOTE

First unlock the housing and then remove the

connectors.

CN34 : Float switch (3P, Red)

CN41 : Remote controller terminal block (3P,

Blue)

(Screw part of terminal block, 2P.)

CN504 : Drain pump (2P, White)

CN67 : Power supply terminal block (5P: Black)

(Screw part of terminal block, 3P.)

CN101 : TC sensor (2P: Black)

CN102 : TCJ sensor (2P, Red)

CN104 : Room temperature (2P, Yellow)

4) Remove screws. (Ø4 x 10, 2 pcs.)

5) Slide the electric parts box toward the arrow

mark and then remove the box from the

bottom side of the main unit.

2. Attachment

1) Attach the electric parts box and then perform

wiring as original.

Notes 1

Check there is no missing or contact failure on

the connectors.

Notes 2

Be sure to perform wiring as original.

2) Attach air filter, suction panel, and electric

parts box as original.

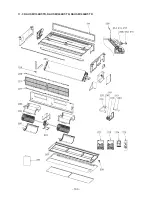

Electric parts

box

f

Electric parts box

Screw

Notch part

1. Detachment

1) Perform work of 1 of

f

.

(In the works of 1 of

f

, removal of the

control P.C. board is available even if you do

not perform works after 4)).

2) Unlock the card edge spacers (5 positions) in the

electric parts box to remove the control P.C. board.

2. Attachment

1) Mount control P.C. board in the electric parts

box as original.

2) Attach the electric parts box as original.

3) Be sure to perform wiring as original in the

electric parts box.

NOTE

Check there is no missing or contact failure on

the connectors.

4) Attach each air filter, suction panel or

electric parts box cover as original.

Control P.C.

board

g

CAUTION

When replacing PC. board,

check no-mex paper is attached.

Summary of Contents for RAV-SM1106BT-E

Page 18: ... 18 ...

Page 19: ... 19 3 WIRING DIAGRAM ...

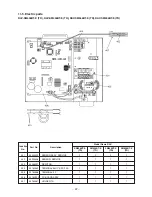

Page 34: ... 34 5 3 Indoor Print Circuit Board MCC 1631 ...

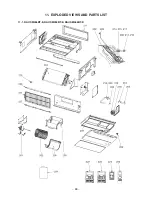

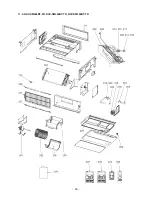

Page 89: ... 89 11 EXPLODED VIEWS AND PARTS LIST 11 1 RAV SM406BT E RAV SM456BT E RAV SM566BT E ...

Page 91: ... 91 11 2 RAV SM806BT E ...

Page 93: ... 93 11 3 RAV SM406BT TR RAV SM456BT TR RAV SM566BT TR ...

Page 95: ... 95 11 4 RAV SM806BT TR ...

Page 98: ... 98 11 6 RAV SM1106BT E RAV SM1406BT E RAV SM1606BT E ...

Page 100: ... 100 11 7 RAV SM1106BT TR RAV SM1406BT TR RAV SM1606BT TR ...