– 15 –

4. Tools

1. Required Tools for R410A

Mixing of different types of oil may cause a trouble such as generation of sludge, clogging of capillary,

etc. Accordingly, the tools to be used are classified into the following three types.

1) Tools exclusive for R410A (Those which cannot be used for conventional refrigerant (R22))

2) Tools exclusive for R410A, but can be also used for conventional refrigerant (R22)

3) Tools commonly used for R410A and for conventional refrigerant (R22)

The table below shows the tools exclusive for R410A and their interchangeability.

Tools exclusive for R410A (The following tools for R410A are required.)

Tools whose specifications are changed for R410A and their interchangeability

No.

c

d

e

f

g

h

i

j

k

Used tool

Flare tool

Copper pipe gauge

for adjusting

projection margin

Torque wrench

Gauge manifold

Charge hose

Vacuum pump adapter

Electronic balance for

refrigerant charging

Refrigerant cylinder

Leakage detector

Usage

Pipe flaring

Flaring by

conventional flare tool

Tightening of flare nut

Evacuating, refrigerant

charge, run check, etc.

Vacuum evacuating

Refrigerant charge

Refrigerant charge

Gas leakage check

R410A

air conditioner installation

Existence of

Whether conventional

new equipment

for R410A

equipment can be used

Yes

∗

(Note)

Yes

∗

(Note)

Yes

No

Yes

No

Yes

No

Yes

Yes

Yes

No

Yes

No

Conventional air

conditioner installation

Whether

conventional equipment

can be used

Yes

∗

(Note)

No

No

Yes

Yes

No

Yes

(Note)

When flaring is carried out for R410A using the conventional flare tools, adjustment of projection

margin is necessary. For this adjustment, a copper pipe gauge, etc. are necessary.

General tools (Conventional tools can be used.)

In addition to the above exclusive tools, the following equipments which serve also for R22 are necessary

as the general tools.

1) Vacuum pump. Use vacuum pump by

attaching vacuum pump adapter.

7) Screwdriver (+, –)

2) Torque wrench

8) Spanner or Monkey wrench

3) Pipe cutter

9) Hole core drill

4) Reamer

10) Hexagon wrench (Opposite side 4mm)

5) Pipe bender

11) Tape measure

6) Level vial

12) Metal saw

Also prepare the following equipments for other installation method and run check.

1) Clamp meter

3) Insulation resistance tester (Megger)

2) Thermometer

4) Electroscope

Summary of Contents for RAV-SM1106BT-E

Page 18: ... 18 ...

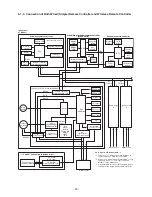

Page 19: ... 19 3 WIRING DIAGRAM ...

Page 34: ... 34 5 3 Indoor Print Circuit Board MCC 1631 ...

Page 89: ... 89 11 EXPLODED VIEWS AND PARTS LIST 11 1 RAV SM406BT E RAV SM456BT E RAV SM566BT E ...

Page 91: ... 91 11 2 RAV SM806BT E ...

Page 93: ... 93 11 3 RAV SM406BT TR RAV SM456BT TR RAV SM566BT TR ...

Page 95: ... 95 11 4 RAV SM806BT TR ...

Page 98: ... 98 11 6 RAV SM1106BT E RAV SM1406BT E RAV SM1606BT E ...

Page 100: ... 100 11 7 RAV SM1106BT TR RAV SM1406BT TR RAV SM1606BT TR ...