– 60 –

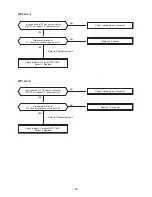

[3] Writing the setting data to EEPROM

The settings stored in the EEPROM of the P.C. board for indoor unit servicing are the factory-set values.

Step 1

Push

SET

,

CL

and

TEST

buttons on the remote controller simultaneously for more than 4 seconds.

∗

In the group control operation, the unit No. displayed for the first time is the header unit No.

At this time, the CODE No. (DN) shows “

10

10

10

10

10

”. Also, the fan of the indoor unit selected starts its operation

and the swing operation starts if it has the louvers.

(The unit No. “

” is displayed if the auto-address setting mode is interrupted in [2] step 2 a)

Step 2

Every time when

UNIT LOUVER

button is pushed, the indoor unit No. in the group control operation are displayed

in order.

(The settings stored in the EEPROM of the P.C. board for indoor unit servicing are the factory-set values.)

Specify the indoor unit No. with its P.C. board replaced to the P.C. board for indoor unit servicing.

(You cannot perform this operation if “

” is displayed.)

Step 3

Select the CODE No. (DN) can be selected by pushing the

/

button for the temperature setting.

• Set the indoor unit type and capacity.

The factory-set values shall be written to the EEPROM by changing

the type and capacity.

1. Set the CODE No. (DN) to “

10

10

10

10

10

”. (without change)

2. Select the type by pushing / buttons for the timer setting.

(For example, Concealed Duct standard type is set to “

0004

”.

Refer to table 2)

3. Push

SET

button.

(The operation completes if the setting data is displayed.)

4. Change the CODE No. (DN) to “

11

11

11

11

11

” by pushing

/

buttons for the temperature setting.

5. Select the capacity by pushing / buttons for the timer setting.

(For example, 80 Type is set to “

0012

”. Refer to table 3)

6. Push

SET

button.

(The setting completes if the setting data are displayed.)

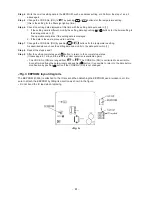

<Fig. 1 RBC-AMT32E>

NOTE: Setting Concealed Duct standard type Indoor Unit model only

7. Using the set temperature

/

buttons, set “

CE

” to the CODE No. (DN).

8. Using the timer time / buttons, set the data. (0001)

9. Push

SET

buttons. ( The setting completes if the setting data are displayed.)

CAUTION

Don’t remove the materials.

No materials. The power I.C. (IC101) may break.

<Fig. 2>

10. Push the

TEST

button to return to the normal stop status.

(It takes approx. 1 min until the remote controller operation is available again.)

3 6 5 1

4 2

00 04

3- 3

10

Summary of Contents for RAV-SM1106BT-E

Page 18: ... 18 ...

Page 19: ... 19 3 WIRING DIAGRAM ...

Page 34: ... 34 5 3 Indoor Print Circuit Board MCC 1631 ...

Page 89: ... 89 11 EXPLODED VIEWS AND PARTS LIST 11 1 RAV SM406BT E RAV SM456BT E RAV SM566BT E ...

Page 91: ... 91 11 2 RAV SM806BT E ...

Page 93: ... 93 11 3 RAV SM406BT TR RAV SM456BT TR RAV SM566BT TR ...

Page 95: ... 95 11 4 RAV SM806BT TR ...

Page 98: ... 98 11 6 RAV SM1106BT E RAV SM1406BT E RAV SM1606BT E ...

Page 100: ... 100 11 7 RAV SM1106BT TR RAV SM1406BT TR RAV SM1606BT TR ...