Installation Manual

‒

20

‒

20-EN

A

A

10

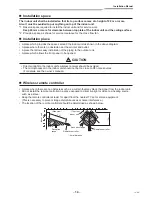

Heat insulator provided

Gas side

Indoor unit shield pipe

Liquid side

Cut the heat insulator of the gas pipe

(locally procured) leaving a 10 mm

overlap with the shield of the shield pipe.

Heat insulator wrapping cross section A-A

Make the slit part of heat insulator to upward.

▼

Insulating the pipes

Insulate the indoor unit completely so there are no gaps using the heat insulator provided.

CAUTION

Securely apply insulation all the way up to the pipe connecting section of the indoor unit so that there

is no exposed area. (the pipe exposed to the outside causes water leak.)

When wrapping the heat insulator around pipes, make sure the slit aperture toward the ceiling surface.

CAUTION

• Bind the auxiliary pipes (two) and power supply wiring and control wiring with facing tape tightly. In

case of leftward piping and rear leftward piping, bind the auxiliary pipes (two) only with facing tape.

Indoor unit

Power supply wiring

Control wiring

Auxiliary pipes

Installation plate

• Carefully arrange pipes so that any pipe does not stick out of the rear plate of the indoor unit.

• Carefully connect the auxiliary pipes and connecting pipes to one another and cut off the insulating

tape wound on the connecting pipe to avoid double-taping at the joint; moreover, seal the joint with

the vinyl tape, etc.

• Since dew results in a machine trouble, make sure to insulate both the connecting pipes.

(Use polyethylene foam as insulating material.)

• When bending a pipe, carefully do it, not to crush it.