Installation Manual

‒

23

‒

23-EN

REQUIREMENT

Tightening with an excessive torque may crack

the nut depending on installation conditions.

Tighten the nut within the specified tightening

torque.

Piping with outdoor unit

• Shape of valve differs according to the outdoor

unit.

For details of installation, refer to the Installation

Manual of the outdoor unit.

Heat insulation

Heat insulation for the pipes should be done

separately for the liquid side and gas side.

Because both of the liquid and gas side pipes

become a low temperature during cooling

operation, suf

fi

cient heat insulation should be

done to prevent condensation.

• Heat insulator with a heat resistance of 120°C or

more must be used for the gas side pipe.

• The pipe connection section of the indoor unit

must be heat insulated securely and compactly

with the attached heat insulator.

Fix with vinyl tape

Local side pipe

Heat insulator

(attached)

Airtight test/Air purge, etc.

For airtight test,air purge, addition of refrigerant,

and gas leak check, follow the Installation Manual

attached to the outdoor unit.

Open fully valves of the outdoor

unit

Open the valve of the outdoor unit fully.

A hexagonal wrench is required for opening the

valve.

For details, refer to the Installation Manual

attached to the outdoor unit.

CAUTION

• Do not scratch the inner surface of the flared

part when removing burrs.

• Flare processing under the condition of

scratches on the inner surface of flare

processing part will cause refrigerant gas

leak.

• Check that the flared part is not scratched,

deformed, stepped, or flattened, and that

there are no chips adhered or other problems,

after flare processing.

• Do not apply refrigerating machine oil to the

flare surface.

* In case of

fl

aring with the

conventional

fl

are tool, pull it out

approx. 0.5 mm more than that

for R22 to adjust to the speci

fi

ed

fl

are size. The copper pipe gauge

is useful for adjusting projection

margin size.

A

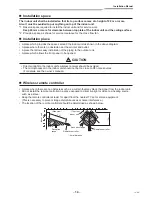

Tightening connection

CAUTION

• Do not apply excessive torque. Otherwise, the

nut may crack depending on the conditions.

(Unit: N•m)

Outer dia. of copper pipe

Tightening torque

6.4 mm (dia.)

14 to 18 (1.4 to 1.8 kgf•m)

9.5 mm (dia.)

33 to 42 (3.3 to 4.2 kgf•m)

12.7 mm (dia.)

50 to 62 (5.0 to 6.2 kgf•m)

15.9 mm (dia.)

68 to 82 (6.8 to 8.2 kgf•m)

q

Tightening torque of flare pipe connections

Incorrect connections may cause not only a gas

leak, but also a trouble of the refrigeration cycle.

Align the centres of the connecting pipes and

tighten the

fl

are nut as far as possible with your

fi

ngers. Then tighten the nut with a spanner and

torque wrench as shown in the

fi

gure.

Work using double spanner