– 69 –

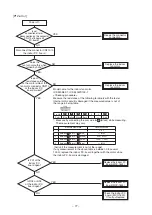

Check code

Location

of

detection

Description

System status

Error detection

condition(s)

Check items (locations)

H16

H16

SMMS

(1 series)

01: TK1 oil

circuit error

02: TK2 oil

circuit error

03: TK3 oil

circuit error

04: TK4 oil

circuit error

I/F

Oil detection

circuit error

All stop

The temperature change of

TK1 cannot be detected even

after Compressor 1 starts

operating.

• Check the TK1 sensor installation.

• Check the TK1 sensor resistant

characteristics.

• Check the misconnection of TK1,

TK2, TK3, or TK4.

• Check the SV3E valve error.

• Check the oil circuit capillary

clogging and non-return valve error.

• Check the hibernating refrigerant in

compressor.

I/F

SMMS

(1 series)

01: TK1 oil

circuit error

02: TK2 oil

circuit error

03: TK3 oil

circuit error

04: TK4 oil

circuit error

Oil detection

circuit error

All stop

The temperature change of

TK2 cannot be detected even

after Compressor 2 starts

operating.

• Check the TK2 sensor installation.

• Check the TK2 sensor resistant

characteristics.

• Check the misconnection of TK1,

TK2, TK3, or TK4.

• Check the SV3E valve error.

• Check the oil circuit capillary

clogging and non-return valve error.

• Check the hibernating refrigerant in

compressor.

I/F

SMMS-i

(4 series)

01: TK1 oil

circuit error

02: TK2 oil

circuit error

03: TK3 oil

circuit error

04: TK4 oil

circuit error

05: TK5 oil

circuit error

Oil level detection

circuit error

All stop

No temperature change is

detected by TK1 despite

compressor 1 having been

started.

• Check for disconnection of TK1

sensor.

• Check resistance characteristics of

TK1 sensor.

• Check for connection error involving

TK1, TK2, TK3, TK4, and TK5

sensors

• Check for faulty operation in SV3E

or SV3F valve.

• Check for clogging in oil equalizing

circuit capillary and faulty operation

in check valve.

• Check for refrigerant entrapment

inside compressor.

No temperature change is

detected by TK2 despite

compressor 2 having been

started.

• Check for disconnection of TK2

sensor.

• Check resistance characteristics of

TK2 sensor.

• Check for connection error involving

TK1, TK2, TK3, TK4, and TK5

sensors

• Check for faulty operation in SV3E

or SV3F valve.

• Check for clogging in oil equalizing

circuit capillary and faulty operation

in check valve.

• Check for refrigerant entrapment

inside compressor.

No temperature

change is detected

by TK3 despite

compressor 3 having

been started.

• Check for disconnection of TK3

sensor.

• Check resistance characteristics of

TK3 sensor.

• Check for connection error involving

TK1, TK2, TK3, TK4, and TK5

sensors

• Check for faulty operation in SV3E

or SV3F valve.

• Check for clogging in oil equalizing

circuit capillary and faulty operation

in check valve.

• Check for refrigerant entrapment

inside compressor.

The temperature change of

TK3 cannot be detected even

after Compressor 3 starts

operating.

• Check the TK3 sensor installation.

• Check the TK3 sensor resistant

characteristics.

• Check the misconnection of TK1,

TK2, TK3, or TK4.

• Check the SV3E valve error.

• Check the oil circuit capillary

clogging and non-return valve error.

• Check the hibernating refrigerant in

compressor.

The temperature change of

TK4 cannot be detected even

after Compressor 4 starts

operating, or the temperature

difference from that of the

other TK sensor changes only

in the specified range for a

given time or longer.

• Check the TK4 sensor installation.

• Check the TK4 sensor resistant

characteristics.

• Check the misconnection of TK1,

TK2, TK3, or TK4.

• Check the SV3E valve error.

• Check the oil circuit capillary

clogging and non-return valve error.

• Check the hibernating refrigerant in

compressor.

Outdoor 7-segment display

Check

code

Sub-code

Main

remote

controller