– 70 –

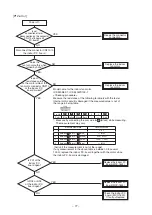

Check code

Location

of

detection

Description

System status

Error detection

condition(s)

Check items (locations)

H16

H16

SMMS-i

(4 series)

01: TK1 oil

circuit error

02: TK2 oil

circuit error

03: TK3 oil

circuit error

04: TK4 oil

circuit error

05: TK5 oil

circuit error

I/F

Oil level detection

circuit error

All stop

No temperature change is

detected by TK4 despite

compressor having been

started.

• Check for disconnection of TK4

sensor.

• Check resistance characteristics of

TK4 sensor.

• Check for connection error involving

TK1, TK2, TK3, TK4, and TK5

sensors

• Check for faulty operation in SV3E

or SV3F valve.

• Check for clogging in oil equalizing

circuit capillary and faulty operation

in check valve.

• Check for refrigerant entrapment

inside compressor.

H25

H25

—

I/F

TD3 sensor

miswiring

(incomplete

insertion)

All stop

Air discharge temperature

(TD3) does not increase

despite compressor 3 being in

operation.

• Check installation of TD3 sensor.

• Check connection of TD3 sensor

connector and wiring.

• Check resistance characteristics of

TD3 sensor.

• Check for defect in outdoor P.C.

board (I/F).

L02

L02

—

Indoor unit Outdoor unit

model mismatch

error

Only the target

unit stopped

An error was found on the

outdoor unit model.

• Check the model name of the

outdoor unit.

• Check the miswiring of the

communication line between indoor

and outdoor.

L03

—

—

Indoor unit Duplicated indoor

header unit

Stop of

corresponding unit

There is more than one

header unit in group.

• Check indoor addresses.

• Check for any change made to

remote controller connection

(group / individual) since indoor

address setting.

L04

L04

—

I/F

Duplicated

outdoor line

address

All stop

There is duplication in line

address setting for outdoor

units belonging to different

refrigerant piping systems.

• Check line addresses.

L06

L06

No. of priority

indoor units

I/F

Duplicated priority

indoor unit (as

displayed on

indoor unit other

than priority indoor

unit)

All stop

More than one indoor unit

have been set up as priority

indoor unit.

• Check displays on priority indoor

unit and outdoor unit.

L07

—

—

Indoor unit Connection of

group control

cable to

standalone indoor

unit

Stop of

corresponding unit

There is at least one stand-

alone indoor unit to which

group control cable is

connected.

• Check indoor addresses.

L08

L08

—

Indoor unit Indoor group /

addresses not set

Stop of

corresponding unit

Address setting has not been

performed for indoor units.

• Check indoor addresses.

Note:

This code is displayed when

power is turned on for the first

time after installation.

L09

—

—

Indoor unit Indoor capacity

not set

Stop of

corresponding unit

Capacity setting has not been

performed for indoor unit.

Set indoor capacity. (DN = 11)

L10

L10

—

I/F

Outdoor capacity

not set

All stop

Jumper wire provided on P.C.

board for servicing I/F P.C.

board has not been removed

as required for given model.

Check model setting of P.C. board for

servicing outdoor I/F P.C. board.

L17

L17

Target indoor

address

I/F

Outdoor unit

model mismatch

error

The outdoor unit model is

duplicate. The Cool/Heat

Flex series 1/2 are duplicate.

• Check the outdoor unit model.

L05

—

—

I/F

Duplicated priority

indoor unit (as

displayed on

priority indoor unit)

All stop

More than one indoor unit has

been set up as priority indoor

unit.

• Check display on priority indoor unit.

No temperature change is

detected by TK5 despite

compressor having been

started.

• Check for disconnection of TK5

sensor.

• Check resistance characteristics of

TK5 sensor.

• Check for connection error involving

TK1, TK2, TK3, TK4, and TK5

sensors

• Check for faulty operation in SV3E

valve.

• Check for clogging in oil equalizing

circuit capillary and faulty operation

in check valve.

• Check for refrigerant entrapment

inside compressor.

Outdoor 7-segment display

Check

code

Sub-code

Main

remote

controller