3 TROUBLESHOOTING FOR PRINTING

64 Client Problems

Client Problems

This section describes how to identify and correct the problems caused by the clients* connected to the

equipment.

*

One of the common examples of clients is a computer that sends a print job to the equipment and makes it perform printing.

Checking the client status

Problem Description

The printing problems are caused by the printer driver settings, network settings, errors in the network

connections, and so forth. First, contact the administrator of the equipment to see if there is one of these kinds

of problems, or see the following sections:

P.60 “Printer Driver Problems”

P.62 “Network Connection Problems”

P.80 “Printing Problems (Network Related)”

Another possible cause is one related to a client. If the print jobs sent from a specific client within a network

fail, the problem may be caused by the client.

The checklist below will help you identify the source of the error and direct you to information resolving the

problem. If the problem persists after you have followed all of the steps, contact your service representative.

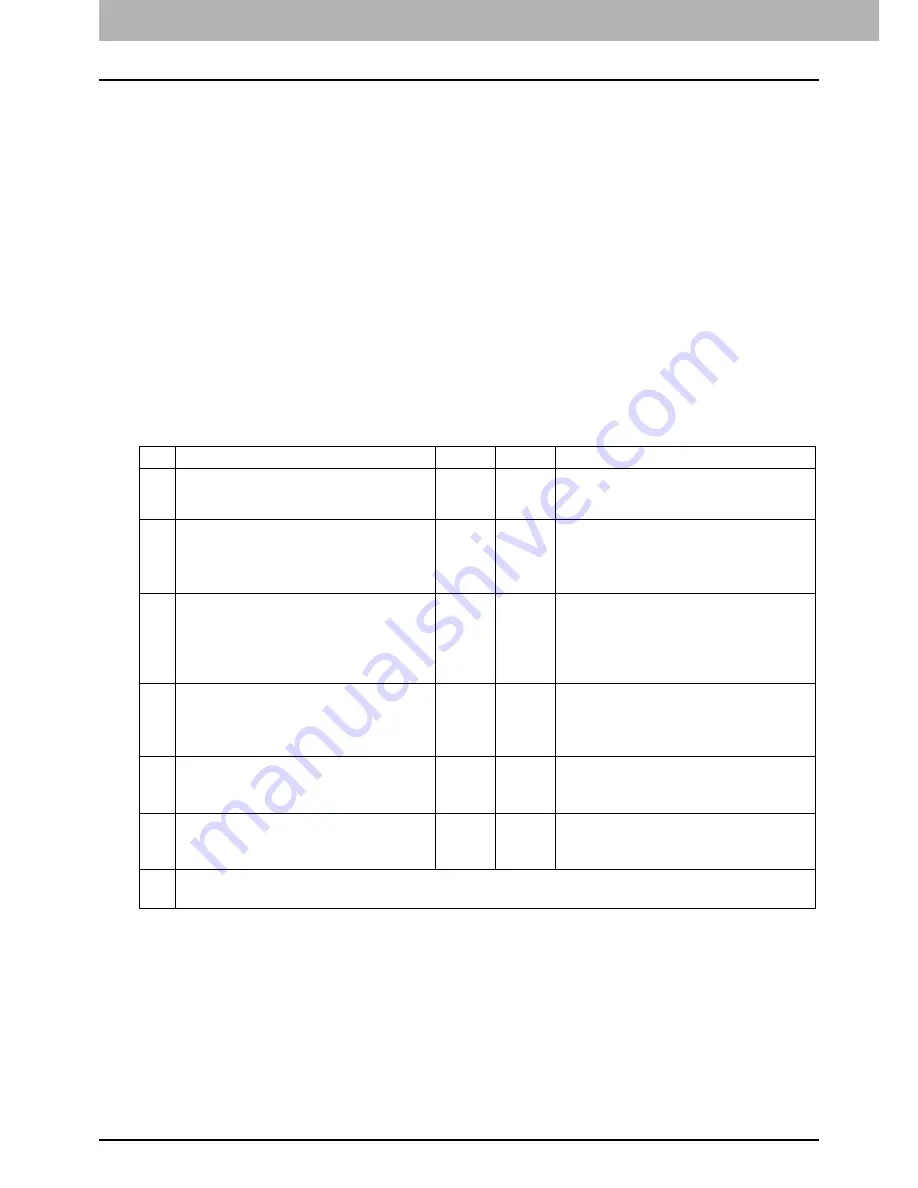

No. Check...

Yes

No

Corrective Action

1

Does the equipment work properly? Are

copy jobs output properly?

Next

Step

Check the device status displayed in

the Device page of TopAccess.

2

See the Device page of TopAccess. Are

the options specified for the job

supported by the hardware

configuration?

Next

Step

If not, delete the job, install the required

components, and try again. Contact

your service representative for further

information.

3

Can you print the jobs from other

clients?

Next

Step

See the following section to fix the

problem.

P.62 “Cannot print with the

equipment (network connection

problems)”

4

Have you ever printed successfully from

this client?

Next

Step

See the following section to fix the

problem.

P.60 “Cannot print (port setting

problems)”

5

Did you set up the printer driver other

than by an SMB connection?

Next

Step

See the following section to fix the

problem.

P.62 “Cannot print with SMB print”

6

(For Macintosh only)

Can you see the equipment you created

in the Selector?

Next

Step

Refer to the

Software Installation

Guide

.

7

At this point, the problem is most likely to be related to a client-side error. Refer to the

Printing Guide

to fix the problem.

Summary of Contents for E-Studio 557

Page 1: ...MULTIFUNCTIONAL DIGITAL SYSTEMS Troubleshooting Guide ...

Page 8: ...6 CONTENTS ...

Page 58: ......

Page 68: ......

Page 90: ......

Page 108: ......

Page 114: ...112 INDEX ...