1 TROUBLESHOOTING FOR THE HARDWARE

10 Messages Displayed on the Touch Panel

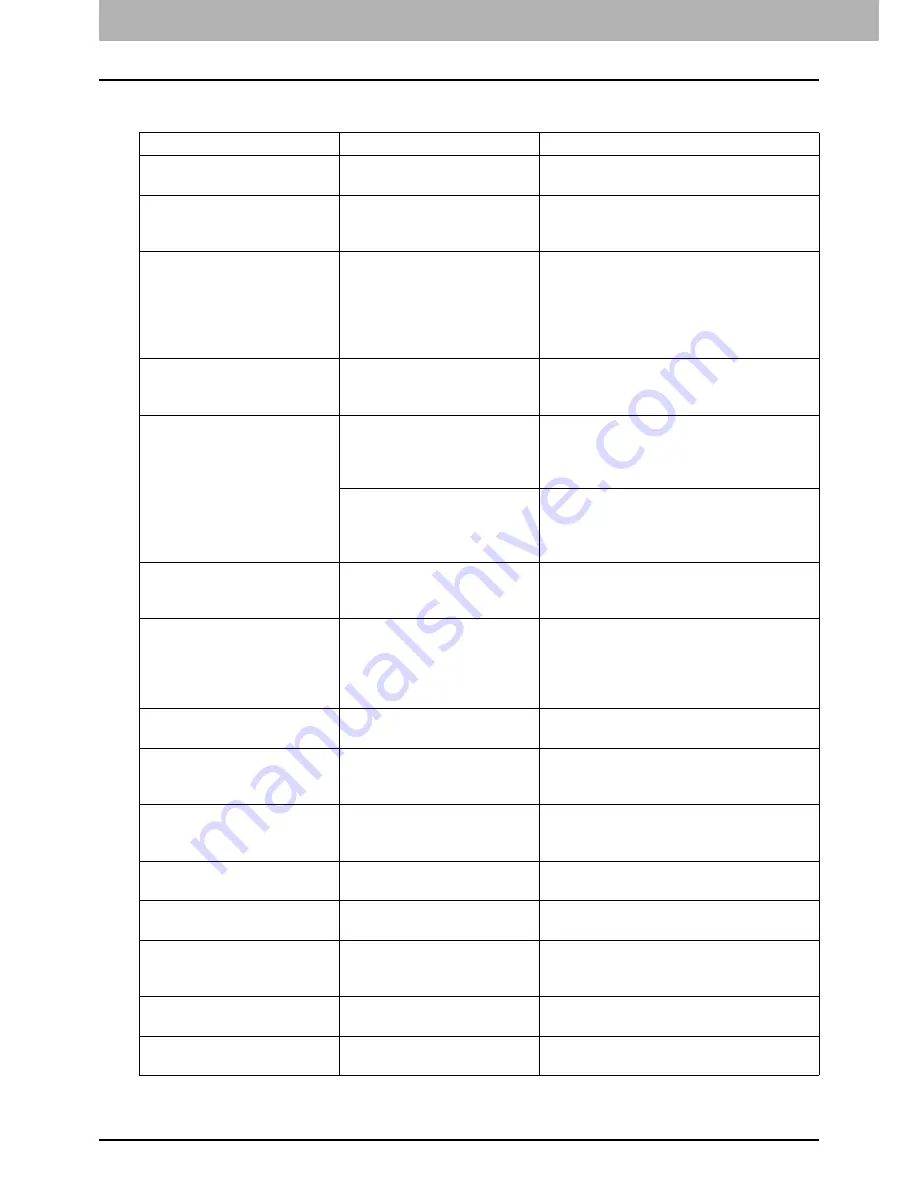

Messages Displayed on the Touch Panel

A message appears on the upper part of the screen to notify users of a problem, etc. The major examples of

problems and how to solve them are described in the table below.

Message

Problem Description

Corrective Action

Close *** cover.

The cover indicated by *** is

open.

Check the cover on the touch panel and

close it.

Misfeed in ***

Paper misfeed has occurred

inside the equipment.

Remove the misfed paper following the

guidance displayed on the touch panel.

P.14 “Clearing a Paper Misfeed”

Check paper size setting on

control

panel for drawer N. Check the

direction or size of the paper.

Paper misfeed has occurred

because of the mismatch

between the paper size

placed in drawer N and the

size registered for the drawer

N in the equipment.

Just removing the misfed paper does not

prevent another paper from being misfed.

Be sure to correctly register the paper size

in the equipment.

P.30 “Clearing paper misfeeds caused

by a wrong paper size setting”

Wait (Performing Self-check)

The equipment is undergoing

maintenance to keep its

imaging quality.

Wait until the adjustment is completed and

the message disappears.

Check the original and set it

again

The original is misfed inside of

the Reversing Automatic

Document Feeder.

Remove the misfed original following the

guidance on the touch panel.

P.16 “Paper misfeed in the Reversing

Automatic Document Feeder (Lower)”

The direction or the size of the

original placed on the

Reversing Automatic

Document Feeder is incorrect.

Check the direction and the size of the

original and then replace it on the

Reversing Automatic Document Feeder.

Then reattempt the operation.

Change direction of original

The orientation of the original

placed on the original glass is

incorrect.

Change the orientation of the original by 90

degrees and place it on the original glass.

Change from this mode

Count over, cannot store

anymore

The number of originals to be

scanned has exceeded the

limit specified with the

department or user code

during scanning.

Ask your administrator for details of setting

the limit for the number of copies.

READY (SADDLE STITCH

TRAY FULL)

The saddle stitch tray of the

finisher is full of paper.

Remove the paper from the saddle stitch

tray of the finisher.

READY (CHECK SADDLE

STITCH STAPLER)

Staple jam has occurred in the

stapler of the saddle stitch

unit.

Remove the jammed staples.

P.38 “Staple jam in the saddle stitch

unit”

READY (CHECK SADDLE

STITCH STAPLER)

No staples are left in the

stapler of the saddle stitch

unit.

Refill the staples.

P.50 “Refilling saddle stitch unit staples”

READY (CHECK STAPLER)

Staple jam has occurred in the

stapler of the finisher.

Remove the jammed staples.

P.35 “Clearing a Staple Jam”

READY (CHECK STAPLER)

No staples are left in the

stapler of the finisher.

Refill the staples.

P.47 “Refilling With Staples”

READY (HOLE PUNCH

DUST BIN IS FULL)

Hole punch dust bin is full of

paper punchings.

Remove the paper punchings.

P.52 “Cleaning the Hole Punch Dust

Bin”

READY (FINISHER FULL)

The receiving tray of the

finisher is full of paper.

Remove the paper from the receiving tray

of the finisher.

READY (INNER TRAY FULL)

The exit tray of the equipment

is full of paper.

Remove the paper from the exit tray of the

equipment.

Summary of Contents for E-Studio 557

Page 1: ...MULTIFUNCTIONAL DIGITAL SYSTEMS Troubleshooting Guide ...

Page 8: ...6 CONTENTS ...

Page 58: ......

Page 68: ......

Page 90: ......

Page 108: ......

Page 114: ...112 INDEX ...