11: TROUBLESHOOTING

©Tormach® 2020

Specifications subject to change without notice.

Page 65

UM10538: Tormach AF50 Autofeed Bandsaw (Version 0320A)

For the most recent version, see tormach.com/support

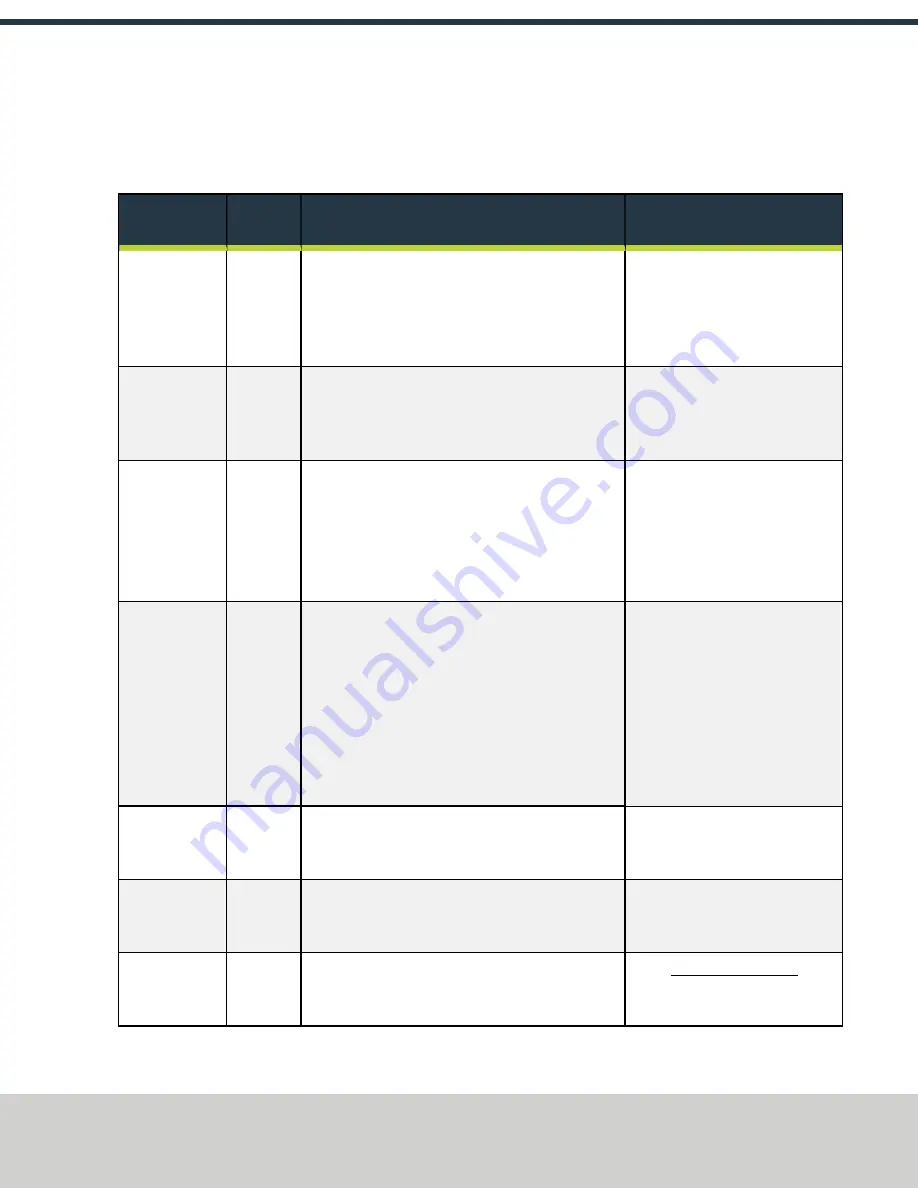

11.2.4 Machine Stalls or It's Underpowered

l

Problem

The machine stalls, or you find that it's underpowered during operations.

l

Cause

The feed rate may be too high, or you may be using the wrong blade.

You May Need

To...

Probability

How-To Steps

Need More?

Raise the

vertical quick-

adjustment nut.

High

During automatic operation, verify that the blade can't

collide with the material while it initially lowers: raise

the vertical quick-adjustment nut. The blade can break

or stall when it drops from the raised position and then

collides with the part before the feed rate is controlled.

For more information, see "Use

Use a different

blade.

High

Verify that the blade's TPI isn't too high, or that the

material isn't too course: you must use the correct

blade for the material. If you're not, you may need to

choose a new blade.

For information, see "Choose a

Adjust the feed

rate or cutting

speed.

High

l

Verify that the feed rate isn't too high: lower the

feed rate, and then do a test cut. Examine the

behavior of the machine as it cuts.

l

Verify that the cutting speed isn't too high: lower

the cutting speed, and then do a test cut.

Examine the behavior of the machine as it cuts.

For information, see "Change the

Feed Rate" (page 31) or "Change

Examine the

workpiece setup.

Medium

l

Manual Operation

Verify that the workpiece

isn't too loose: use the handwheel to tighten the

clamp on the front vise. If necessary, use a jig to

hold the workpiece.

l

Automatic Operation

Examine the vise clamps:

verify that there is 1/8 in. or less of a gap

between the clamps and the material. Then,

verify that the vise jaw clamping pressure isn’t

set too low for the material.

For information, see "Use

Automatic Mode" (page 34) or "Use

Adjust the

blade's tension.

Low

Verify that the blade isn't too tight or too loose

between the wheels. If necessary, use the tensioner on

the top of the saw head to adjust the blade's tension.

For information, see "Change a

Examine the

main power

supply voltage.

Low

Test the hot lines to confirm that they have the correct

voltage on both legs.

For information, see "Electrical

Replace the

motor bearings.

Low

Rotate the shaft: if there's rotational grinding or if the

shaft is loose, this indicates that you must replace the

motor bearings.

Email [email protected] to

contact Tormach Technical Support

for guidance on how to proceed.