6.1 CHOOSE A BLADE

Using the correct blade for the material is important to reduce

cost and to operate the bandsaw efficiently. Because there's a

wide variety of bandsaw blade types, you must first know the

specifications of the material you want to cut.

Choosing a blade depends on a number of different factors.

Use this section as a reference; for more information, see your

blade manufacturer's reference materials.

Note:

AF50 Autofeed Bandsaw blades are 93 in. × 3/4

in. × 0.35 in.

To choose a blade, determine the following:

1.

Teeth Per Inch (TPI)

Based on the size and shape of

the material, select the TPI. A high TPI cuts slower and

smoother, while a low TPI cuts faster and rougher. While

cutting, you must always have three teeth engaged with

the part.

Material Thickness Range

TPI Range

1/8 in. (6 mm) to 1/4 in.

10 to 14

1/4 in. to 1/2 in. (12 mm)

8 to 12

1/2 in. (12 mm) to 1 in.

6 to 10

1 in. to 2 in.

5 to 8

2 in. to 4 in.

3 to 4

4 in. to 7 in.

2 to 3

7 in. to 12 in.

1-2/5 to 2-1/2

2.

Tooth Form

Select the tooth form (the shape of the

cutting edge). The tooth form affects how the blade cuts

through the material.

3.

Tooth Set

Based on the required chip clearance, select

the tooth set (the angle at which the tooth is offset from

the blade). The particular tooth set is what carries the

chip away from the cut, and is important for surface

finish.

6.2 CHANGE A BLADE

The bandsaw arrives with a blade installed. To change the

blade, complete the following steps in the order listed:

6.2.2 Verify the Blade Installation

Note:

For simplicity, you must verify the blade

installation before you set the saw head down.

6.2.1 Install a New Blade

1. Put on work gloves, eye protection, and any other

appropriate personal protective equipment. We

recommend a long-sleeved shirt and long pants.

2. Power off the bandsaw and disconnect it from the main

air supply.

a. Push the Emergency Stop button on the operator

panel to lock it into the disabled position.

b. Turn the Main Disconnect switch to

OFF

.

Mains power is disconnected from the machine.

c. Disconnect the air line from your site from the input

port on the FRL Filter-Regulator-Lubricator.

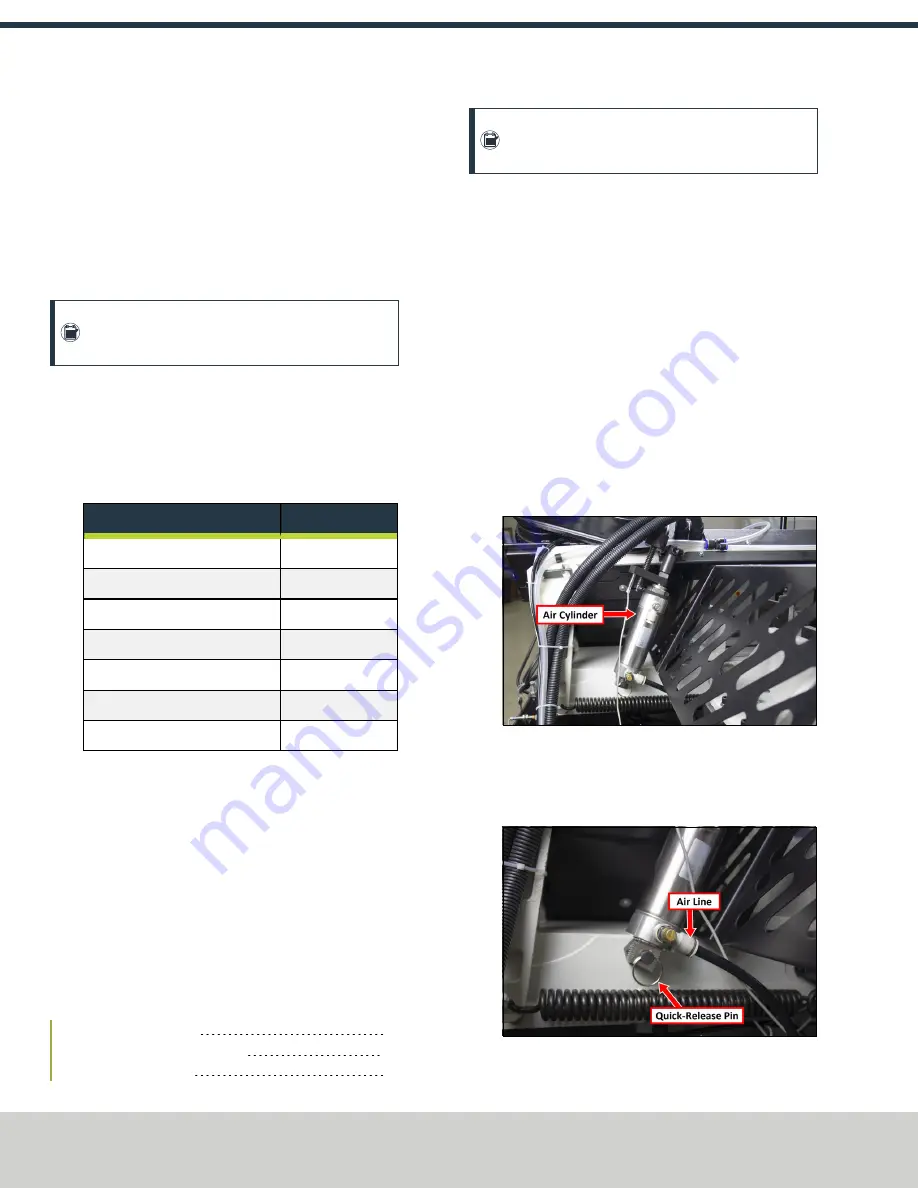

3. On the back of the machine, identify the air cylinder, as

shown in the following image.

Figure 6-1: Air cylinder on the back of the machine.

4. Turn the air line valve, which allows you to access the air

cylinder's quick-release pin, as shown in the following

image.

Figure 6-2: Quick-release pin on the air cylinder.

©Tormach® 2020

Specifications subject to change without notice.

Page 28

UM10538: Tormach AF50 Autofeed Bandsaw (Version 0320A)

For the most recent version, see tormach.com/support

6: BASIC OPERATIONS