7

c

2

c

1

c

38

c

37

c

36

c

35

c

34

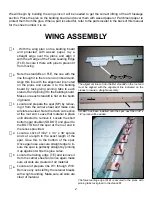

Sand the leading edge smooth. Install and

glue the leading edge (LE). Use pins to sta-

bilize it and tape to pull it snugly against

FLE.

Plane and sand the leading edge shape to

contour. Use the leading edge template to

guide your work

Locate three Wing Tip (WT) parts and use

the registration pins to laminate the three

together to make the wing tip block. Glue

this assembly to W11 and when cured,

plane and sand to shape.

In the circles above are two gussets made from 1/4” triangle

stock, use on both sides. The arrow in th lower part is indica

-

tion the glue fillet between the cap strip and the rib.

Sand the trailing edge in the aileron bay flat

and install and glue the Aileron Bay Trailing

Edge (ABTE). Sand ABTE to contour with

the trailing edge and wing tip. Use a knife

blade to open up the slot for the hinges and

test fit the hinges for easy installation, they

should fit slightly snug.

Use some scrap balsa to fill in at the front

and back the servo plate (SP) opening. Use

the Servo Plate as a guide.

This concludes the assembly of one wing panel. Place the remaining wing panel plans on the building

board and repeat all the above Wing Assembly Steps. Joining the wing halves will be done later after

we assemble the belly pan.

Assembling the Ailerons

Each aileron is laminated up from two (AIL)

parts using the registration pins to assem-

ble them. After laminating two AIL,s sand

the leading edge and both ends smooth.

NOTE: Although the ailerons will not be permanently attached until after the model is covered, cutting

the hinge slots and temporarily fitting the assembly together will make the final assembly mush easier.

Place the aileron next to the trailing edge

and mark the location of the hinges on the

aileron, then cut slots to accept the hinges.