9

c

4

After curing, trim the front and back to

formers BP-1 in front and BP-10 at the

back. When trimming the plastic at F10, trim

it close and then sand it to exactly match

the angle and face of F10.

The belly pan assembly will be installed onto the wing assembly while attached to the fuselage as-

sembly this is as far as we can go for now. Put these assemblies aside and proceed with building the

fuselage.

After installing the former assembly, sand both ends flush

with the end formers.

glue available at craft stores. Apply a liberal

bead to all surfaces that will contact the belly

pan and install it. Set this aside to thoroughly

cure.

c

3

c

2

c

1

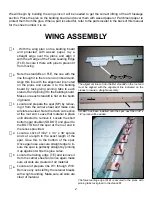

Both wing halves completed and ready for joining. Note the

carbon fiber joiner and 1/8” dowel have been Epoxied into

the bottom wing half.

JOINING THE WING HALVES

Cut a 1/2” length of 1/8” dowel and round

over one end. Install it in the hole provided

in W1 just ahead of TE, let it protrude about

1/8”. Do this in one wing half only, this will

engage the hole in the opposite wing half

to align the wing halves when joining them.

Use Epoxy to install the 1/8” x 5/16” x 4”

carbon fiber joiner in one wing half and let

this cure.

Apply Epoxy to one W1 on one of the wing

panels. Apply a liberal amount in the slot for

the carbon fiber joiner. You can access this

though the hole in W1. Join the wing halves

and install and glue W13. Put the assembly

aside to cure.

c

4

Cut two lengths of 3/16” dowel to 1-1/4”

long. Round over one end and smooth the

other end. Use Epoxy to install these in the

hole provided in W13. Make sure they are

glued to W12 as well, leave about 1/4” pro-

truding.

Completed wing assembly, the correct dihedral is set by W13.

Note the Cable opening plate. NOTE: In this photo the belly

pan has been installed. You will install that later in the build.