6

c

33

c

32

c

31

Assemble the center section sheeting from

one TCS and one BCS section and glue it

to ribs W1, W2 and W3 as well as the spar

and TE.

Installing the bottom leading edge sheet-

ing. The curve on the bottom leading edge

should not require wetting the balsa, install

it dry. Apply a bead of alphabetic resin (El-

mer’s or Titebond) to all ribs and the FLE.

Use a bead of medium CA on the top of the

spar and place the leading edge sheeting in

place and into contact with the spar. Hold it

in that position until the CA has cured. Place

the assembly on the bench with the sheeting

on the bottom and run a sharp blade along

the edge of FLE and trim the sheeting flush

with FLE. Then use strips of masking tape

around the leading edge to pull the sheeting

into contour and into contact with the ribs

and FLE. Set aside to cure.

c

30

c

29

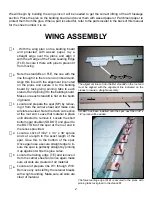

Install and glue the Wing Servo Rails (WSR)

into the notches provided in W7 and W8.

Note that the screw holes should be to the

inside or towards each other. Use 1/4” piec-

es of 1/4” triangle stock to gusset these to

the ribs.

Install the servo rails and use some 1/4” length pieces of 1/4”

triangle stock as gussets between the ribs and the rails.

Sand the trailing edge to contour with the

ribs between W7 and W10 in preparation

for installing the trailing edge sheeting. In-

stall and glue the trailing edge sheeting to

ribs W1 through W7, the trailing edge and

the top trailing edge sheeting. Use clamps,

clothes pins or weights to maintain contact

with the ribs, trailing edge and top sheeting

until the glue cures.

When installing the bottom trailing edge, use plenty of clamps

along the trailing edge. A slight taper on both sheets will yield

a nice crisp trailing edge.

The cap strips are laser cut and should re-

quire little or no trimming to install. Note that

cap strips 7 and 8 on the bottom are notched

for the servo opening, after installing 7 and

8 on the bottom, run a bead of glue along

the interface of the rib and the cap strip on

the outside of the servo bay for support. In-

stall all cap strips, top and bottom, the num-

bers on the cap strips corresponds to the rib

they will attach to.

The cap strips on the bottom of ribs 7 and 8 are shaped to

accommodate the servo opening. The material indicated by

the arrows is scrap fill. You can use the servo mount for po

-

sitioning of the fill.