10

c

3

c

2

c

1

Locate the four wheel pant halves. Note

that two of them have dimples in them for

the attachment system. Drill the four small-

er dimples out with a 1/16” bit. Drill out the

larger dimple with a 1/8” drill bit.

Trim the parts down to about 1/4” from the

edge of the part in preparation for trim-

ming out with the trim tool. You will need a

smooth flat surface for the next operation.

While holding the part flat on a smooth sur

-

face make many very shallow cuts around

the periphery of the part. Do not attempt to

cut through but instead just try to score it.

It may take ten or fifteen very light passes,

if you put too much pressure it can deflect

the blade. Some parts of the plastic are

thinner than others and if you do happen

to break through, no problem just back off

on the pressure and continue. After you are

satisfied with the scoring, fold the edge of

the rim inward and it should break along

the score. Continue all the way around the

part. If there are any irregularities, a couple

swipes on a flat piece of sand paper should

clean up the edge.

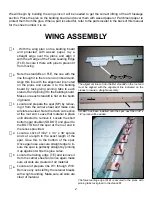

Landing Gear Assembly

The landing gear and wheel pants are assembled as a unit and then installed in the wing. To assemble

the wheel pants they must first be trimmed to shape. This is easily accomplished using the plastic trim

-

ming tool but first we need to assemble the tool. Locate both parts of the trim tool. Note the tracing of

the X-Acto blade on one part. Use thin CA to glue the X-Acto blade to the part. Then glue the second

Trim Tool part to the first encapsulating the blade.

RIGHT: The trimming tool components, a new blade must

be used when assembling the tool. The tool is used to only

score the plastic. The scrap can then be removed by flexing

at the score. This will give you a clean straight edge to work

with.

Scoring the plastic with the trimming tool will give you a clean

straight edge to work with.

With a good score, the plastic will snap along the score line

leaving a straight edge.