17

Post-purge:

A post-purge is always necessary on oil installations. The factory default post-purge time period is 2 minutes. Just as a chimney contin-

ues to draft after the burner has shut-down, the SS2 will continue to run to clear the vent system of residual gases. The duration of the post-purge cycle

is adjustable from 0 to 16 minutes. We recommend a minimum of 2 minutes post-purge on oil.

Draft Adjustment:

The SS2 Draft Adjustment, located on the rear housing of the SS2 is used for setting up the appliance for proper draft. See “Draft

Adjustment Procedure” on pages 15, 16.

Burner Adjustment:

Verify that the over-fire draft matches that recommended by the heating equipment manufacturer. Adjust the combustion effi-

ciency and smoke characteristics to optimum levels of performance. See “Draft Adjustment Procedure” on pages 15, 16.

Combustion Air:

Modern construction methods and materials have reduced natural air infiltration rates to extremely low levels. Even older homes can

lack adequate air for combustion, when insulation upgrades and other weatherization methods have been installed. It is recommended that fuel burning

appliances have dedicated sources of outside air for combustion. This may be simply accomplished by running a properly sized duct from outdoors and

terminating it near the burner air intake. Accessory air intakes are available that connect to the burner motor, using it to pull in the outdoor air. The

Tjernlund IN-FORCER

TM

Combustion Air Intake tempers the raw outdoor air as it is delivered to the burner. Without a source of outdoor air for combus-

tion, a tight home's negative pressures will draw odors back through the venting system during the appliance off cycle.

Chronic Oil Odor Conditions:

Certain features of the specific appliance and installation, e.g. high heat-retention combustion chamber; low-mass, dry-

base; piping system design; oil impurities; air in lines, can all contribute to an increased production of oil odor and cannot always be anticipated. For

extreme cases of oil odor nuisance Tjernlund recommends the practice of post-purging the burner during the vent system post-purge. A burner post-

purge cycle can eliminate any shortcomings of compatibility between the specific installation and the SS2. Burner post-purge kits, such as, Tjernlund's

P/N 950-2043, are available from most oil equipment distributors. Burner post-purge kits should be used on installations where the combustion air is

being adequately supplied, yet oil odors continue.

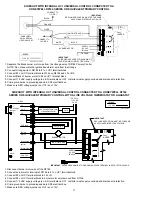

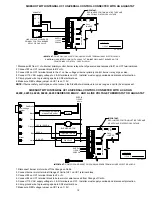

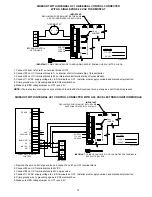

TROUBLESHOOTING ELECTRICAL PROBLEMS

The following guide is intended to be used if a problem occurs during the use of the SS2 side wall vent system. It may be necessary to measure volt-

age during troubleshooting.

Extreme caution must be exercised to prevent injury.

If you are unable to determine the defective part with the use of

this guide, call your Tjernlund distributor or Tjernlund Products direct at 1-800-255-4208 for further assistance.

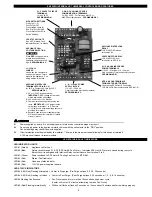

LED STATUS & FAULT INDICATORS

LED INDICATOR LIGHTS

LED #1 (Amber)

Appliance call for heat.

LED #2 (Blue)

Safety circuit through P1 & P2 (SS2 Limit & Fan Prover). Indicates SS2 Limit & Prover are closed during run cycle.

Burner circuit is energized with Interlock Relay contact closure from terminal 3 to 4.

LED #3 (Green)

Power switched to SS2 motor & Cooling Fan from L to MTR & M.

LED #4 (Red)

Status / Fault indicator.

LED #5 (Red)

Used as a status indicator.

LED #6 (Red)

115 VAC power supplied to board.

LED STATUS INDICATORS

LED #4 & #5 (Red) Flashing Alternately = Venter in Pre-purge. (Pre-Purge options 0, 5, 20, 35 seconds)

LED #4 & #5 (Red) Flashing in Unison = Venter in Post-Purge. (Post-Purge options 0, 30 seconds or 1, 2, 4, 8, 16 minutes)

LED #4 Flashing Continuously*

= Fan Prover opened for more than 10 seconds during burner cycle.

(Venter will run for 10 minutes, attempting to make Fan Prover)

LED #5 (Red) Flashing Intermittently

= With no call for heat, flashes 3 seconds on / 3 seconds off if microcontroller is working properly.

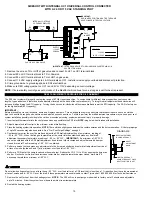

LED FAULT INDICATORS

Fault conditions are indicated by counting the number of times LED #4 (Red) flashes.

LED #4 Flashes 2 Times

Fan Prover was in electrically closed position prior to venter operation.

LED #4 Flashes 3 Times*

Fan Prover does not close within 60 seconds after call for heat.

LED #4 Flashes 4 Times*

Fan Prover did not re-close after 10 minutes of Venter operation.

LED #4 Flashes 5 Times*

Fan Prover opened for more than 10 seconds during burner cycle but closed within 10 minutes.

* Investigate causes of Fan Prover not making, i.e; Firing burner at capacities or temperatures exceeding Venter limits, excessive vent pipe runs, high

winds, plugged / kinked Fan Prover sensing tube or a faulty Fan Prover. Reset SS2 High Limit. If Limit was tripped and SS2 fires, investigate cause

of high heat.

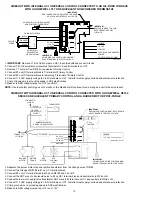

CHECKING MEMORY FOR LAST FAULT CODE

IMPORTANT:

Prior to accessing the fault code memory, note the settings of the dip switches so that they can be returned to their original Pre / Post-

Purge positions. When power is supplied to the UC1 use caution when moving dip switches.

The last fault code can be retrieved at any time by setting all dip switches 1-8 to the up, or “on” position. The last fault code, or lack there of, will be indi-

cated by counting the number of times LED 4 flashes. By moving any of the dip switches back to their original position, the fault code will be cleared.

NOTE:

The UC1 board must have its 115 VAC power supply present when any of the (1-8) dip switches are moved back to their original position for

the fault code to clear.

IMPORTANT:

Fault codes will automatically be displayed after a fault condition occurs. If the call for heat interlock signal or 115 VAC power is

removed, the UC1 board will reset and the fault will be stored in memory instead of displayed. Any new fault will replace any previous fault.

IMPORTANT

Any adjustment to the draft setting must be followed by an over-fire draft measurement and necessary adjustments to the

primary air intake on the burner and barometric draft control. See “Draft Adjustment Procedure” on pages 15, 16.