5

Pre-Purge

Post-Purge

Pre-Cycle Fan Prover

Status Check Activated

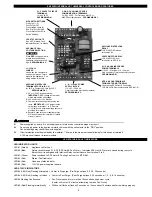

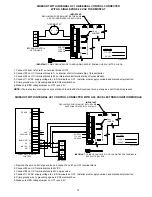

DIP SWITCH NUMBERING

1

ON

2

3 4 5 6 7 8

9

LED FAULT INDICATORS

Fault conditions are indicated by counting the number of times LED #4 (Red) flashes.

LED #4 Flashes 2 Times

Fan Prover was in electrically closed position prior to venter operation.

LED #4 Flashes 3 Times*

Fan Prover does not close within 60 seconds after call for heat.

LED #4 Flashes 4 Times*

Fan Prover did not re-close after 10 minutes of Venter operation.

LED #4 Flashes 5 Times*

Fan Prover opened for more than 10 seconds during burner cycle but closed within 10 minutes.

* Investigate causes of Fan Prover not making, i.e; Firing burner at capacities or temps exceeding Venter limits, excessive vent pipe runs, high winds,

plugged / kinked Fan Prover sensing tube or faulty Fan Prover. Reset SS2 High Limit. If Limit was tripped and SS2 fires, investigate cause

of high heat.

tripped and SS2 fires, investigate cause of high heat.

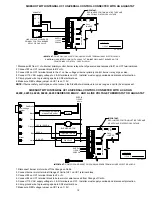

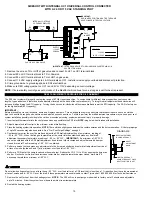

CHECKING MEMORY FOR LAST FAULT CODE

IMPORTANT:

Prior to accessing the fault code memory, note the settings of the dip switches so that they can be returned to their original Pre / Post-

Purge positions. When power is supplied to the UC1 use caution when moving dip switches.

The last fault code can be retrieved at any time by setting all dip switches 1-8 to the up, or “on” position. The last fault code, or lack there of, will be indi-

cated by counting the number of times LED #4 flashes. By moving any of the dip switches back to their original position, the fault code will be cleared.

NOTE:

The UC1 board must have its 115 VAC power supply present when any of the (1-8) dip switches are moved back to their original position for the

fault code to clear.

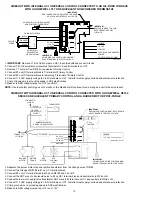

PRE / POST PURGE AND PROVER STATUS CHECK DIP SWITCH SETTINGS

Remove power to SS2 and heating equipment when installing, servicing or changing dip switch settings. Failure to do so may result in

personal injury and/or equipment damage. LED #6 (RED) should not be on if 115 VAC supply power is removed from the control.

Pre-purge

Used for longer vent runs to get draft fully established throughout the vent system prior to burner ignition. Also beneficial for negative pressure prone

environments.

IMPORTANT:

Nuisance equipment lockouts may occur if our pre-purge is running in conjunction with and is longer than any equipment

timing circuit. Pre-purge settings must be shorter than burner control lockout time unless wired prior to burner control timing circuit (i.e. aquastat / thermostat).

Post-purge

A Venter post-purge has been factory set at 2 minutes. Confirm that dip switch #5 is in the up or "on" position. Oil fired equipment requires that the

post-purge be long enough to eliminate post cycle nozzle drip odor. A longer post-purge may be necessary for longer vent runs or high heat retention,

refractory lined combustion chambers. A shorter post-purge may be desired for gas installations.

IMPORTANT:

Fault codes will automatically be displayed after a fault condition occurs. If the call for heat interlock signal or 115 VAC power is

removed, the UC1 board will reset and the fault will be stored in memory instead of displayed. Any new fault will replace any previous fault.

LED 1 AMBER

LED 2 BLUE

LED 3 GREEN

LED 4 RED

LED 5 RED

LED 6 RED

POWER LED

ON

ON

ON

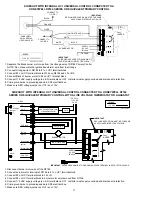

POST-PURGE SETTINGS

(SEE “POST-PURGE” ABOVE PRIOR TO SETTING)

ON

4

3

4

8

6

5

7

3

5 6 7 8

3 4 5 6 7 8

3

7

5

4

6

8

4

3

4

8

6

5

7

3

5 6 7 8

3 4 5 6 7 8

4 Minutes

8 Minutes

16 Minutes

1 Minute

0 Seconds

30 Seconds

2 Minutes

PRE-PURGE SETTINGS

(SEE “PRE-PURGE” ABOVE PRIOR TO SETTING)

1 2

1 2

1 2

1 2

0 Seconds

5 Seconds

20 Seconds

35 Seconds

P1 & P2 PRE-CYCLE FAN PROVER STATUS CHECK

The Pre-Cycle Prover Status Check is activated from the factory. When activated the UC1

Universal Control checks across P1 & P2 safety circuit (SS2 Prover & Limit) to verify that the Fan

Prover switch is “Open” upon a call for heat and not stuck “Closed”.

Pre-Cycle

Prover Status

Check Activated

9

1 9