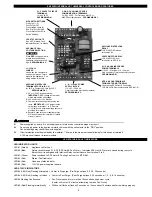

SPECIFICATIONS

Motor:

115/1/60, 3000 RPM, 1/25 HP, 1.6 FLA, Ball Bearing Permanently Lubricated.

Fan Proving Switch:

Non-adjustable set point of -.40” W.C. on pressure drop.

High Limit:

Manual reset N/C contacts, open at 170oF + 8oF (77oC + 5oC).

UC1 Universal Control:

See UC1 Universal Control Board Features on page 4.

Cooling Fan:

115/1/60, RPM 3000, AMPS .2, CFM 105, DB Level 50.

Pre-Purge:

Options (0, 5, 20, 35 seconds);

Post-Purge:

Factory set at 2 minutes, Options (0, 30 seconds or 1, 2, 4, 8, 16 minutes).

See page 5 for Pre / Post-purge options.

2

GENERAL INFORMATION

Each SS2 is electrically factory line tested before shipment.

After opening carton, inspect thoroughly for hidden damage. Impeller should rotate freely. If any damage is found notify freight carrier and your distrib-

utor immediately and file a concealed damage claim.

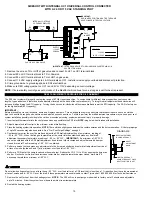

INSTALLATION RESTRICTIONS

1. The SS2 may only be installed on flame retention head oil burners for oil installations.

2. The SS2 may not be installed on condensing type or solid fuel burning appliances, incinerators or incinerating toilets.

3. Oil installations must have a barometric draft control. The SS2 may only be installed on gas appliances equipped with a draft hood, draft diverter or

barometric draft control.

4. The SS2 may not be connected to a natural draft chimney.

5. The SS2 shall not be installed where flue gas temperatures exceed 650oF (343oC) at its inlet. Flue gas temperature verification:

A) On oil fuel, verify flue gas temperature at appliance inlet is at or above 250oF (121oC) after 5 minutes of operation during setup. See “Oil Draft

Adjustment Procedure” on page 16, step 9.

AND

B) After 15 minutes of operation, measure flue gas temperature to verify it is not more than 650oF (343oC) at SS2 inlet.

6. Vent runs of over 15 linear feet (4.5 meters) require the use of an approved, insulated vent connector to prevent problems related

to condensation.

Improper installation, adjustment, alterations, service or maintenance can cause injury, property damage or death. Refer to this manual. For

assistance or additional information consult a qualified installer, service agency or the equipment supplier.

Do not exceed the recommended input range of the SS2. Under no circumstances shall the minimum draft adjustment be used for the larger

input range of this product. Improper adjustment may result in the dispersion of flue products (carbon monoxide) into

the building interior causing carbon monoxide poisoning or death.

If oil nozzle is changed or other equipment is added perform “Draft Adjustment Procedure” on pages 15, 16 again.

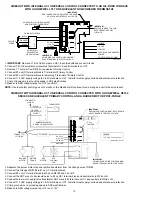

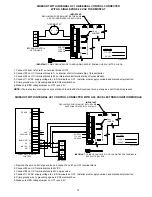

FRONT VIEW

SIDE VIEW

REAR VIEW

Rough-In

8 1/2” J

10 1/2” I

A

32 1/2" 28 1/2"

B

5 1/2"

C

22 3/8"

D

7 3/4"

E

8"

F

12 1/2"

G

13 1/4"

H

10 1/2"

I

8 1/2"

J