45

K-Cube Position Aligner

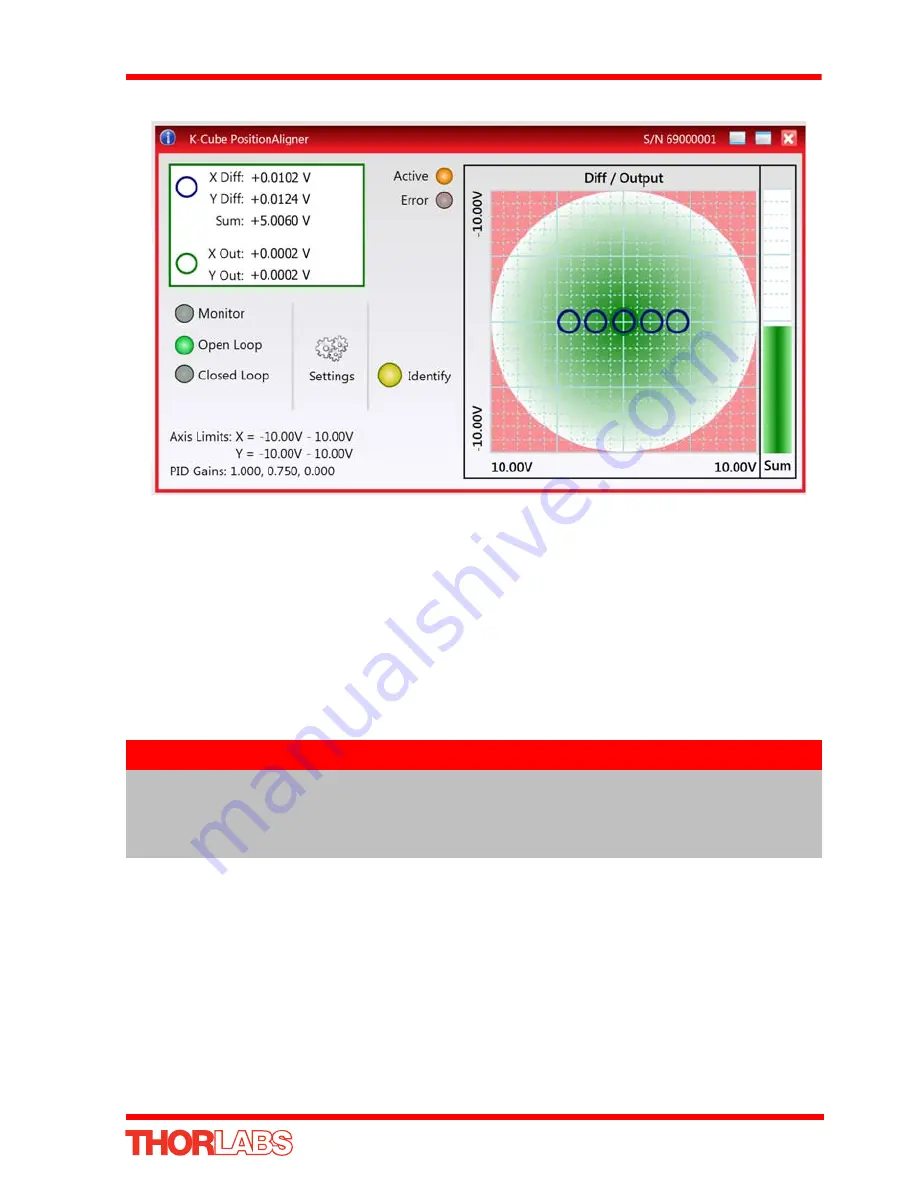

Fig. 5.8 X-axis Position Demand Sense Check

6) Check that the piezo controller connected to the Y DIFF connector, is driving the

Y-axis piezo actuator. Turn the control knob on the piezo controller to increase the

piezo drive voltage. The laser beam should move along the Y axis with very little

X axis movement. If the beam moves in the X-axis (or di agonally), the piezo

controller is connected to the wrong actuator.

7) When the Y-axis piezo voltage is increased, if the spot moves towards the top, the

demand sense is positive. If the sp ot moves towards the bottom, the demand

sense is negative.

8) Press the CLOSED LOOP button on the GUI panel to select ‘Closed Loop’ mode,

i.e. the CLOSED LOOP LED is lit.

The position aligner unit now takes over the alignment, and controls the piezo

units to drive the piezo mirror to direct the laser beam to the central position. The

beam position within the sensor array is indicated by the ‘Grid’ display.

9) Depending on the position of other components in the system, it is possible that

the travel range of the piezo actuators driving the mirror is not sufficient to position

the beam on the detector array. In this case, the piezos should be centered and

the actuators on the o ther turning mirrors should be adjusted to reposition the

beam as follows:

Note

The default settings for the Position Demand Sense is ‘Positive’, which is

correct for the set up shown in Fig. 5.2. If the check described at item (7)

shows a negative demand sense, then it will be necessary to change the

Position Demand Sense

parameter in the Settings panel - see Section 6.2.