INSTALLATION

16

4.3.

Filling the system

After completing all the hydraulic connections, the circuit may be filled with water. After filling

the system, open the radiators air valves to get rid of the air in the installation.

Verify that the installation pressure is according to the technical feature of the boiler. The

pressure must be verified through the boiler’s manometer. An additional manometer should be

installed on the cold water inlet to verify the cold pressure, at the lowest point of the installation,

at a point close to the boiler.

The whole installation must remain under nominal pressure for at least 10 minutes. During this

period, check that all the connections are tight and there are no water leakages. Make sure that

during this period no pressure drop appears.

After firing the boiler, make sure the network functions properly at working temperature and

pressure.

The hardness of the mains water supply affects the boiler’s life span. It is

recommended to use a water softener if water hardness exceeds 15

o

f.

Do not fill the system at the working pressure! When the boiler will be heated,

the water pressure will raise. Filling pressure must be at least 1 bar lower than

working pressure!

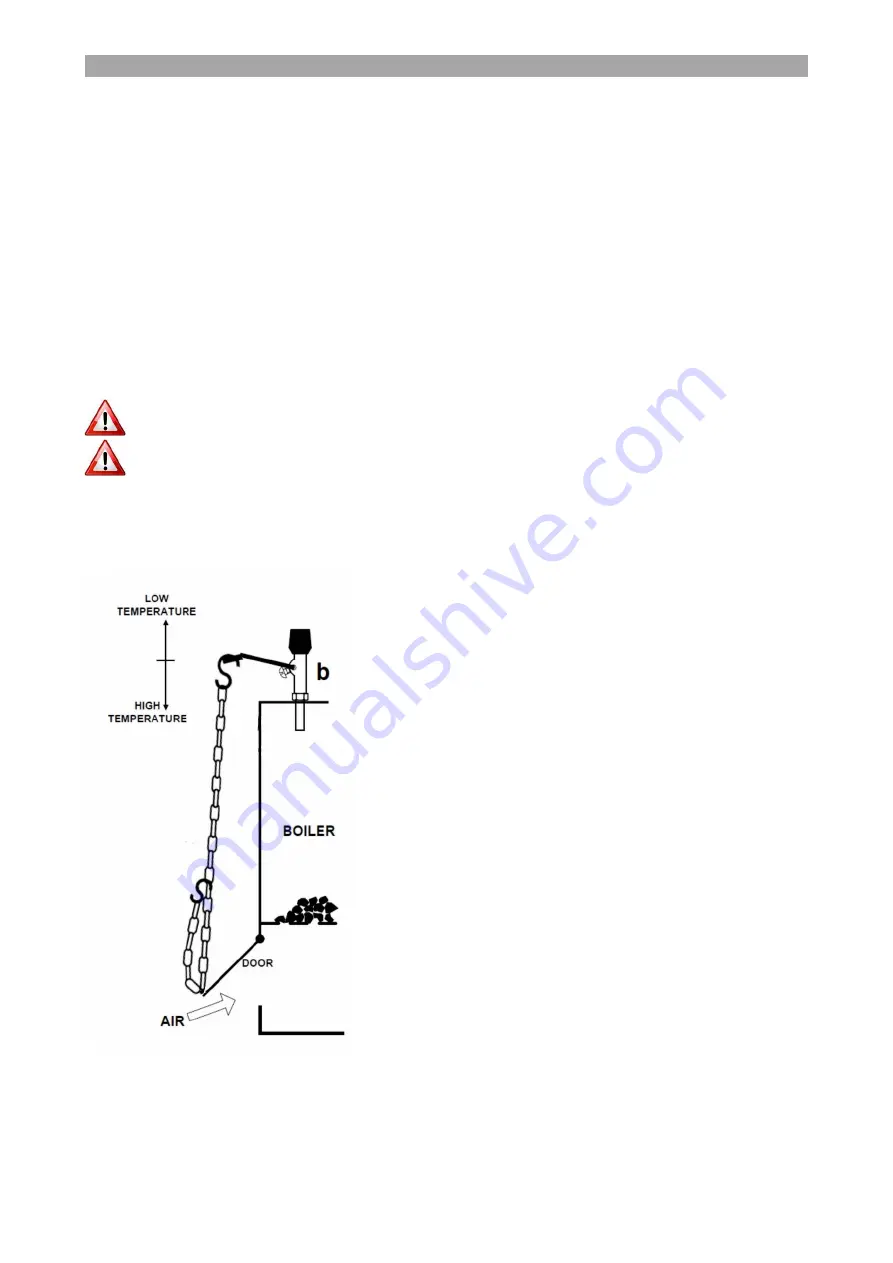

4.4.

Chain thermostat installation

ECOTWIN boiler is equipped with air door on the lower part

and is delivered with chain thermostatic regulator.

Install the regulator at the connection pipe on the upper

side of the boiler and pass the chain through the hook

provided on the air door.

Choose the desired boiler temperature from the

thermostat head (red scale is valid).

The thermostatic regulator controls the boiler temperature

by controlling the supply of combustion air. The chain

length must be adjusted so that when the set temperature

is reached the air door is in closed position and no air is

supplied.