All installations and services must be performed by qualified service personnel.

20

condensate, which causes the tank to rust. It is also recommended to use a water trap or additives

to prevent condensate accumulation.

If the tank is above the burner, and gravity oil feed to the burner is permitted, a single line system

may be used. The line should have a gradual slope downward of approximately 1/2 inch per foot,

or more, to a point directly below where it is connected to the pump. Installing the line with a

downward slope will help prevent the formation of air pockets in the line.

IMPORTANT:

An oil safety valve or a delayed-action solenoid valve is required with all gravity

feed oil supply systems.

IMPORTANT:

The oil storage tank must be free of water, sludge and scale to prevent excessive

wear and possible damage to furnace oil pump and burner nozzle. A fuel oil filter installed in the

oil supply line to the burner is required.

OIL FILTER:

For all installations, use a low micron, oil filter with the capacity to trap particles

10 microns in diameter, or greater. Filtering the oil supply helps to prevent nozzle clogging. Install

the oil filter inside the building between the tank shutoff valve and the burner. The filter cartridge

should be replaced at least once a year. The filter body should be thoroughly cleaned before

installing a new cartridge.

Summary of Contents for OME-72D36

Page 2: ......

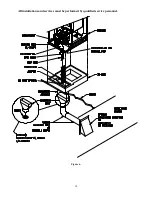

Page 7: ...All installations and services must be performed by qualified service personnel 4a...

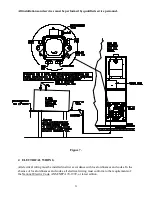

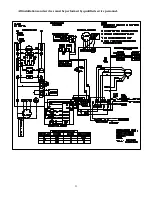

Page 21: ...All installations and services must be performed by qualified service personnel 18 Figure 6...

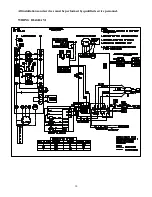

Page 34: ...All installations and services must be performed by qualified service personnel 31...

Page 53: ...All installations and services must be performed by qualified service personnel 50...

Page 54: ...All installations and services must be performed by qualified service personnel 51...

Page 55: ......