All installations and services must be performed by qualified service personnel.

19

H. FUEL PIPING

Sizing and installation of fuel lines must be in accordance with federal, state and local regulations.

1. Oil Tank and Piping

:

All local codes and ordinances take precedence with regard to tank and oil lines.

All lines must have oil shutoff valves, a good pipe joint compound approved for use with oil

on all pipe threads, no kinks; no sharp bends and be properly tested for leaks. Flare fittings

are recommended for tubing.

:

Do not run the oil pump dry for more than five minutes.

Your furnace is factory equipped to operate on No. 2 distillate fuel (domestic heating) oil. In very

cold weather, No. 1 distillate fuel oil may be used. Your oil supplier should be contacted for

recommendations.

:

Do not use motor oil or any fuel heavier than No. 2 fuel oil..

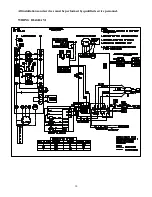

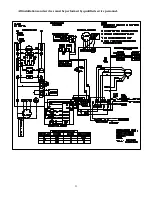

Burners are most commonly installed with a single stage fuel pump (refer to Figure 7). This type

of fuel pump, when connected with a supply line only, is satisfactory where the fuel supply is level

with, or above, the burner. This type of installation permits gravity flow of oil to the burner. When

it is necessary to “lift” (raise) oil to the burner, a return line should be connected between the fuel

pump and tank. This requires insertion of the “by-pass” plug into the fuel pump. If the lift exceeds

approximately 10 feet, a two-stage pump should be installed with a return line. When a return line

is used with either single or two-stage pumps, air is automatically returned to the tank, making the

unit self-purging.

Use of continuous runs of heavy wall copper tubing is recommended. Always use flare fittings.

Avoid use of fittings in inaccessible locations.

Avoid running tubing against any type of

heating unit and across ceiling or floor joists.

If possible, install the tubing under the floor. Specific information on piping, fuel pump

connections, lift capabilities and tank installations is provided in the fuel pump manufacturer’s

instructions.

If the oil tank is located inside the building and the tank capacity is between 10 and 660

gallons, it shall not be located within 5 feet horizontally from any source of heat, or oil-

burning appliance. Furthermore, the oil tank shall not block access to utility service meters,

switch panels, and shutoff valves.

If an underground tank used, the top of the tank should be below all piping in order to prevent oil

discharge through a broken connection. Underwriters Laboratories requirements now stipulate

that all 275 gallon and larger tanks have a bottom outlet. This is to prevent the accumulation of

Summary of Contents for OME-72D36

Page 2: ......

Page 7: ...All installations and services must be performed by qualified service personnel 4a...

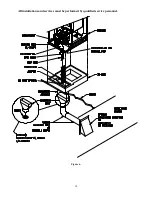

Page 21: ...All installations and services must be performed by qualified service personnel 18 Figure 6...

Page 34: ...All installations and services must be performed by qualified service personnel 31...

Page 53: ...All installations and services must be performed by qualified service personnel 50...

Page 54: ...All installations and services must be performed by qualified service personnel 51...

Page 55: ......