3

Chillers designed for use with a remote air-cooled

condenser and the remote condensers themselves

ship with a nitrogen holding charge. Check the

remote condenser for signs of leaks prior to rigging.

This will ensure no coil damage has occurred after

the unit left the factory. The condenser ships with

the legs removed. Mount the legs to the condenser

using the provided nuts, bolts, and washers.

Unit Storage

When storing the unit it is important to protect it

from damage. Blow out any water from the unit;

cover it to keep dirt and debris from accumulating or

getting in, and store in an indoor sheltered area that

does not exceed 145°F.

Installation - Chiller

Unit Location

The unit is available in many different configurations

for various outdoor environments. Refer to the

proposal and order acknowledgement document for

the equipment to verify the specific design

conditions in which it can operate. When considering

where to locate the unit, consult the local code

requirements as well as the NEC (National Electrical

Code).

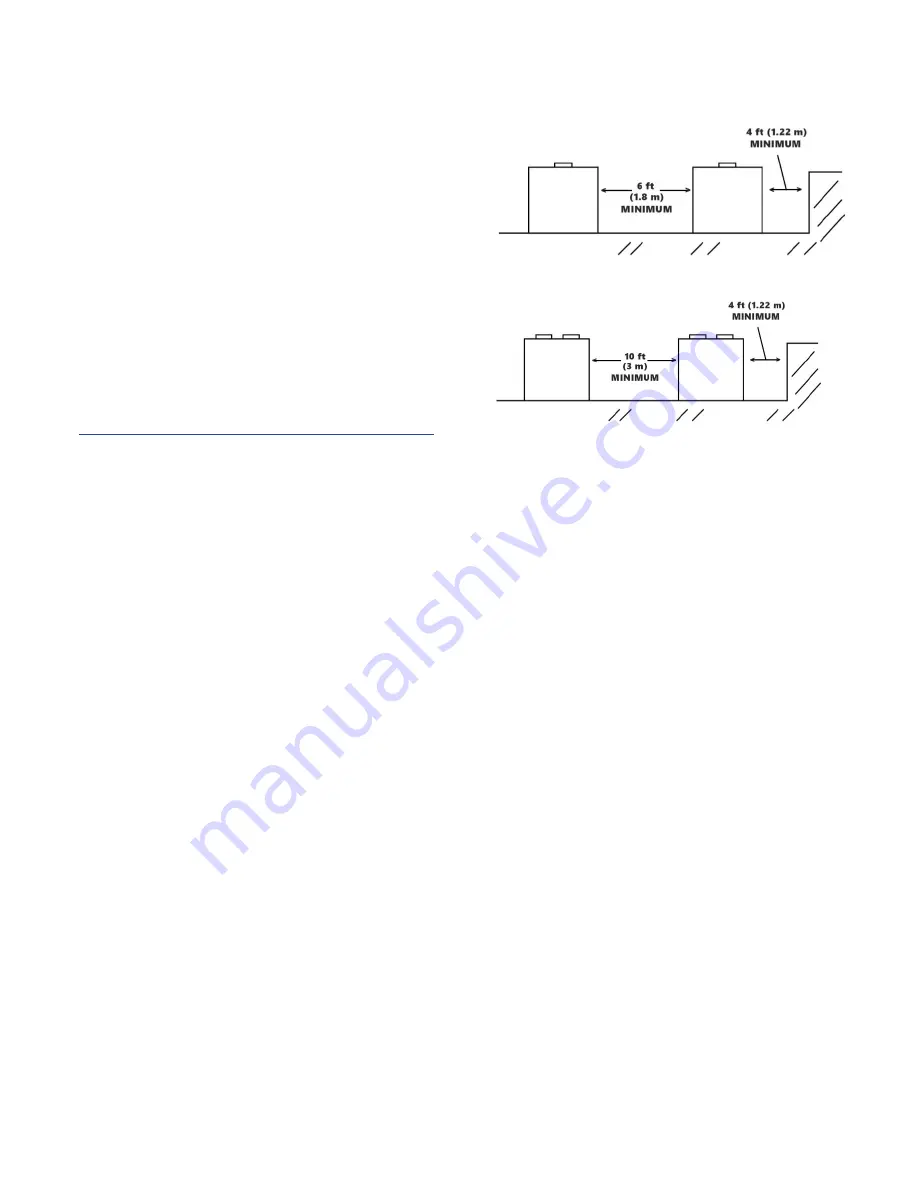

To ensure proper airflow and clearance space for

proper operation and maintenance, ensure the

condenser airflow is unrestricted on both the inlet

and outlet of the chiller. Refer to Figure 1 and

Figure 2 for minimum allowable clearance around

the chiller and to minimize the potential for air

recirculation. It is acceptable to reduce the clearance

on the control panel side to 4 feet while still meeting

NEC code and without impeding performance. When

installing multiple chillers in the same location, the

minimum separation between the sides of the

chillers may be reduced to 6 feet without sacrificing

performance provided the remaining sides are

unrestricted. For acceptable clearance with layout

involving more than two chillers, please contact

factory. Avoid locating piping or conduit over the

unit to ensure easy access with an overhead crane or

lift to lift out heavier components during

replacement or service.

Consider locating the condenser where fan noise

and vibration transmission into nearby workspaces is

unlikely.

Figure 1 – KSE 40 to 60 Unit Location

Figure 2 – KSE 80 to 120 Unit Location

Mounting Foundation

Install the unit on a rigid, non-warping mounting

pad, concrete foundation, or level floor suitable to

support the full operating weight of the equipment.

When installed the equipment must be level within

¼ inch over its length and width. When vibration

isolators are required, mount them at the locations

shown in.Figure 3.

Rigging

The chiller has a frame to facilitate easy movement

and positioning with a crane provided proper lifting

bars, spreader bars, and rigging is used. Use

spreader bars to keep cables or chains clear of the

unit frame and sides. Follow proper rigging methods

to prevent damage to components. Avoid impact

loading caused by sudden jerking when lifting or

lowering the chiller. Use pads where abrasive surface

contact may occur as shown in Figure 4.

Summary of Contents for Accuchiller KSE

Page 1: ......

Page 2: ......

Page 10: ...4 Figure 3 Mounting Platform Figure 4 Rigging...

Page 37: ...31 Notes...

Page 38: ...32...

Page 39: ......