5.9 Defrost Thermostat & Timer

The defrost thermostat is attached to the refrigerant

suction tube between the accumulator and compressor.

If the low side refrigerant temperature drops due to

excessive frost formation on the evaporator coil, the

thermostat opens. The compressor is then cycled off

and on by the defrost timer. The blower will continue to

run, causing air to flow through the evaporator coil and

melt the ice when the compressor is off. When the air

temperature and/or humidity increase, the evaporator

temperature will rise and the thermostat will close to end

the defrost cycle.

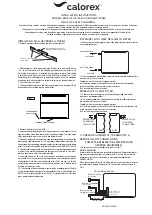

Figure 4: Electrical Schematic of HI-E Dry 100

5.10 Condensate Pump

Condensate is automatically pumped when the water

level in the pump’s reservoir rises to close the float

switch.

If the pump is unable to empty its reservoir due to a

pump failure or blocked condensate hose, a pump safety

float switch is triggered before the reservoir overflows.

The switch turns off the compressor via its relay.

To replace the condensate pump:

1. Unplug the unit & remove the front cover.

2. Disconnect the 2 hoses from the pump.

3. Cut the pump lead wires near the old pump.

4. Remove the 2 nuts from the unit side that hold the

pump to the side.

5. Attach the new pump with 2 nuts.

6. Connect the new pump wiring.

7. Connect the hoses to the new pump. Carefully

route the hoses so they do not contact the copper

refrigerant lines or the compressor shell.

RED

RELAY

DKBLU

GRY

RED

AUTO

AUTO

RELAY CONTACTS

DEFROST

CONTROL

DEFROST

CONTROL

VIO

ON

ON

BLK

BLK

BLK

WHT

VIO

YEL

SWITCH

MOTOR

BRN

WHT

COMPRESSOR

COMPRESSOR

COMPRESSOR

OVERLOAD

PART NO. REV.

4023609

C

RUN

CAPACITOR

RUN

CAPACITOR

YEL

BRN

TIMER

TIMER SWITCH

WHT

WHT

WHT

PNK

MOTOR

WHT

BLK

BLK

BLK

BLK

GRN

115VAC,

60HZ, 1PH

CONDENSATE PUMP

FLOAT

SWITCH

PUMP FLOAT

SWITCH

SAFETY

SWITCH

C

NO

1

4 6 1

C

S

R

2

3

5

NC

BLK

ORG

ORG

ORG

BLOWER

SWITCH

BLOWER

SWITCH

BLOWER

MOTOR

BLOWER MOTOR

PUMP MOTOR

TIMER MOTOR

RELAY COIL

PUMP SAFETY

SWITCH

HUMIDISTAT

HUMIDISTAT

4 6

0

1

3

5

C

S

R

Made in U.S.A.

Therma-Stor LLC, Madison, WI

800-533-7533 or Local 608-222-5301

www.thermastor.com

7

www.thermastor.com • [email protected]

Toll-Free 1-800-533-7533

www.sylvane.com 1-800-934-9194