OPERATION

30

Tennant T3e (03--07)

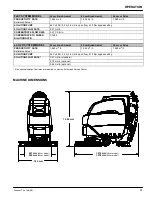

MACHINE SPECIFICATIONS

MODEL

43 cm Brush Assist

50 cm Brush Assist

50 cm w/ Drive

LENGTH

1,219 mm

1,276 mm

1,276 mm

WIDTH

507 mm

549 mm

549 mm

HEIGHT

1,093 mm

1,093 mm

1,093 mm

MINIMUM AISLE TURN

1,257 mm

1,308 mm

1,308 mm

WEIGHT

92 kg

93 kg

98 kg

WEIGHT WITH BATTERIES

143 kg

154 kg

175 kg

RECOVERY TANK CAPACITY

Includes Demisting Chamber

57 L

57 L

57 L

SOLUTION TANK CAPACITY

40 L

40 L

40 L

DRIVE SYSTEM

Brush Assisted

Brush Assisted

Transaxle, 24 V, .104 kW

TRAVEL SPEED, MAXIMUM

n/a

n/a

73 m /min

PRODUCTIVITY RATE

Theoretical

1,880 m

2

h

2,210 m

2

h

2,210 m

2

h

PRODUCTIVITY RATE

Estimated Actual

785 m

2

h

940 m

2

h

1,490 m

2

h

CLEANING PATH WIDTH

430 mm

500 mm

500 mm

BRUSH PRESSURE

22.7 kg Minimum

40.8 kg Maximum

22.7 kg Minimum

40.8 kg Maximum

22.7 kg Minimum

40.8 kg Maximum

SOLUTION FLOW RATE

1.5 L/min

1.5 L/min

1.5 L/min

SQUEEGEE WIDTH

763 mm

763 mm

763 mm

BRUSH MOTOR

.746 kW, 200 rpm, 24 V, 42 A

VACUUM MOTOR

.373 kW, 300 W, 2--stage 5.7, 24 V, 13 A

WATER LIFT -- AIR FLOW

1,016 mm -- 1.84 L

3

/m

BATTERIES

Qty 2, 12 V

Qty 2, 12 V

Qty 2, 12 V

BATTERY CAPACITY

105 Ah @ 20 h rate (WET)

130 Ah @ 20 h rate (WET)

155 Ah @ 20 h rate (WET)

RUN TIME PER CHARGE*

2.5 Hours

2.5 Hours

3.0 Hours

ON--BOARD BATTERY

CHARGER

120/230 VAC, 5.5 A, 50/60 Hz, 24 VDC, 11 A output

TOTAL POWER CONSUMPTION

28 A nominal @ 22.7 kg

brush pressure

29 A nominal @ 22.7 kg

brush pressure

30 A nominal @ 22.7 kg

brush pressure

34 A nominal @ 40.8 kg

brush pressure

35 A nominal @ 40.8 kg

brush pressure

36 A nominal @ 40.8 kg

brush pressure

VOLTAGE DC

24 VDC

24 VDC

24 VDC

PROTECTION GRADE

IPX3

IPX3

IPX3

DECIBEL RATING AT

OPERATOR’S EAR, INDOORS.**

68.5 dBA

68.5 dBA

68.5 dBA

VIBRATION AT CONTROLS

<2.5 m/s

2

<2.5 m/s

2

<2.5 m/s

2

GRADE LEVEL, MAX.

Scrubbing 5% (3

°

),

Transporting 8% (5

°

)

Scrubbing 5% (3

°

),

Transporting 8% (5

°

)

Scrubbing 5% (3

°

),

Transporting 8% (5

°

)

* Run times are based on Continuous Scrubbing Run Times.

** Sound levels (ISO 11201) as recommended by the American Association of Cleaning Equipment Manufacturers (AACEM) and OSHA.