Temperature Control Units : Veteran with LXG Series Instrument

Page: 70

TEMPTEK, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Email: [email protected]

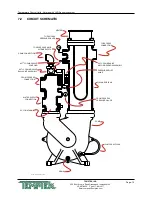

6.1 MECHANICAL SYSTEM

A.

MOTOR/PUMP ASSEMBLY.

The unit pump is a multi-

component assembly serving to circulate water through

the process system. The pump will increase the system

pressure between 35 - 50 PSI over the plant water

supply pressure. The pump is driven by an electrical

motor.

1.

Pump casing.

The pump casing is an exclusive

design. The casing is cast of iron and flanged to

accept the heater/discharge and cooling tanks.

The casing is the support element in the pump/

motor assembly and is secured to the unit base.

2.

Pump adapter.

The pump adapter is the mating

element between the pump casing the electric

motor. The adapter is machined to accept the

pump seal flush line. The stationary pump seal

member is set in the seal cavity of the pump

adapter.

3.

Electrical motor.

The electric motor is a dual

voltage, 3 phase, ODP motor. The motor serves

to turn the pump impeller creating process flow.

4. Impeller.

The impeller is custom designed for

the unit and creates the higher flow (gpm) from

standard HP ratings.

5.

Pump Seal.

The pump seal prevents water

leakage from the pump adapter. The seal is

made up of three items: The stationary member

(seated in the seal cavity), the rotating member

(placed on the motor shaft) and the tension

spring.

6.

Pump seal flush.

The pump seal flush is a flow

diverter which serves to “cleanse” the pump seal

assembly of debris which may lodge on the seal

and create a leak.

B. HEATER.

The heater is a dual voltage, flange mounted

immersion heater set in the pump discharge cylinder. The

heater elements have a stainless steel sheath. Electrical

supply to the heater is provided via a mercury contactor.

C.

HEATER/PUMP DISCHARGE CYLINDER.

The heater/

pump discharge cylinder is a custom cast tank. The

tank is flanged mounted to the pump casing. Reinforced

machined bosses accept the “to process/high temperature limit” sensor probe and the “to

process” connection.

Electric Motor

Pump Casing

Pump Adapter

Stationary member

Seal flush tube

Impeller

Summary of Contents for Veteran VT LXG Series

Page 2: ......

Page 6: ...Page 6 THIS PAGE INTENTIONALLY BLANK ...

Page 20: ...Page 20 THIS PAGE INTENTIONALLY BLANK ...

Page 42: ...Page 42 THIS PAGE INTENTIONALLY BLANK ...

Page 48: ...Page 48 THIS PAGE INTENTIONALLY BLANK ...

Page 68: ...Page 68 THIS PAGE INTENTIONALLY BLANK ...

Page 95: ...END 2021 TEMPTEK INC RE 20210323 ...

Page 96: ......