Temperature Control Units : Veteran with LXG Series Instrument

Page: 82

TEMPTEK, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Email: [email protected]

8.3 OPERATION OF MOLD PURGE

A.

The mold purge system includes valves and piping that when activated and supplied with

compressed air will expel process water from the mold or process to the central water

return line or drain.

B.

Mold Purge is an optional feature and not included on all units. The function of the Mold

Purge requires the purchase on the option.

C.

The Mold Purge parameter must be enabled to operate the mold purge. Advance to

the Main Menu and select Options. Within the Options menu, select Mold Purge. Select

Enable to enable the Mold purge system. Press the Select button to acknowledge and

save the selection.

D.

The mold purge feature is used when the pump is turned off and has been cooled

to below 85°F.

E.

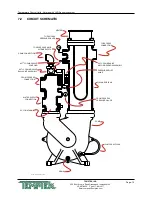

The operation of the mold purge is as follows (see illustration) :

1.

Stop the pump, maintain electrical power to unit.

2.

Close the water supply ball valve.

3.

Connect a regulated air supply to mold purge compressed air connection.

Note: Air supply should be regulated approximately 10 PSI above drain line

pressure.

4.

Mold Purge is activated by selecting the mold purge item from the Utilities menu.

Mold purge is started immediately.

If the pump is running, the follow message will be displayed.

If the pump is not running, the mold purge will start.

Summary of Contents for Veteran VT LXG Series

Page 2: ......

Page 6: ...Page 6 THIS PAGE INTENTIONALLY BLANK ...

Page 20: ...Page 20 THIS PAGE INTENTIONALLY BLANK ...

Page 42: ...Page 42 THIS PAGE INTENTIONALLY BLANK ...

Page 48: ...Page 48 THIS PAGE INTENTIONALLY BLANK ...

Page 68: ...Page 68 THIS PAGE INTENTIONALLY BLANK ...

Page 95: ...END 2021 TEMPTEK INC RE 20210323 ...

Page 96: ......