Part 2 Analysis Unit

Model 3010MA

Teledyne Analytical Instruments

74

Cyclo hexane C

6

H

12

-1.56

Nitric

oxide

NO

+40.00

Ethane C

2

H

6

-0.43

n-Octane

C

8

H

18

-2.50

Ethylene C

2

H

4

-0.26

n-Pentane

C

5

H

12

-1.45

Helium He

+0.30

Propane C

3

H

8

-0.86

n-Heptane C

7

H

16

-2.10

Propylene

C

3

H

6

-0.55

n-Hexane C

6

H

14

-1.70

Vinyl

chloride

-0.63

Hydrogen H

2

+0.24

Water

H

2

O -0.02

Hydrogen bromide HBr

-0.61

Xenon Xe

-0.95

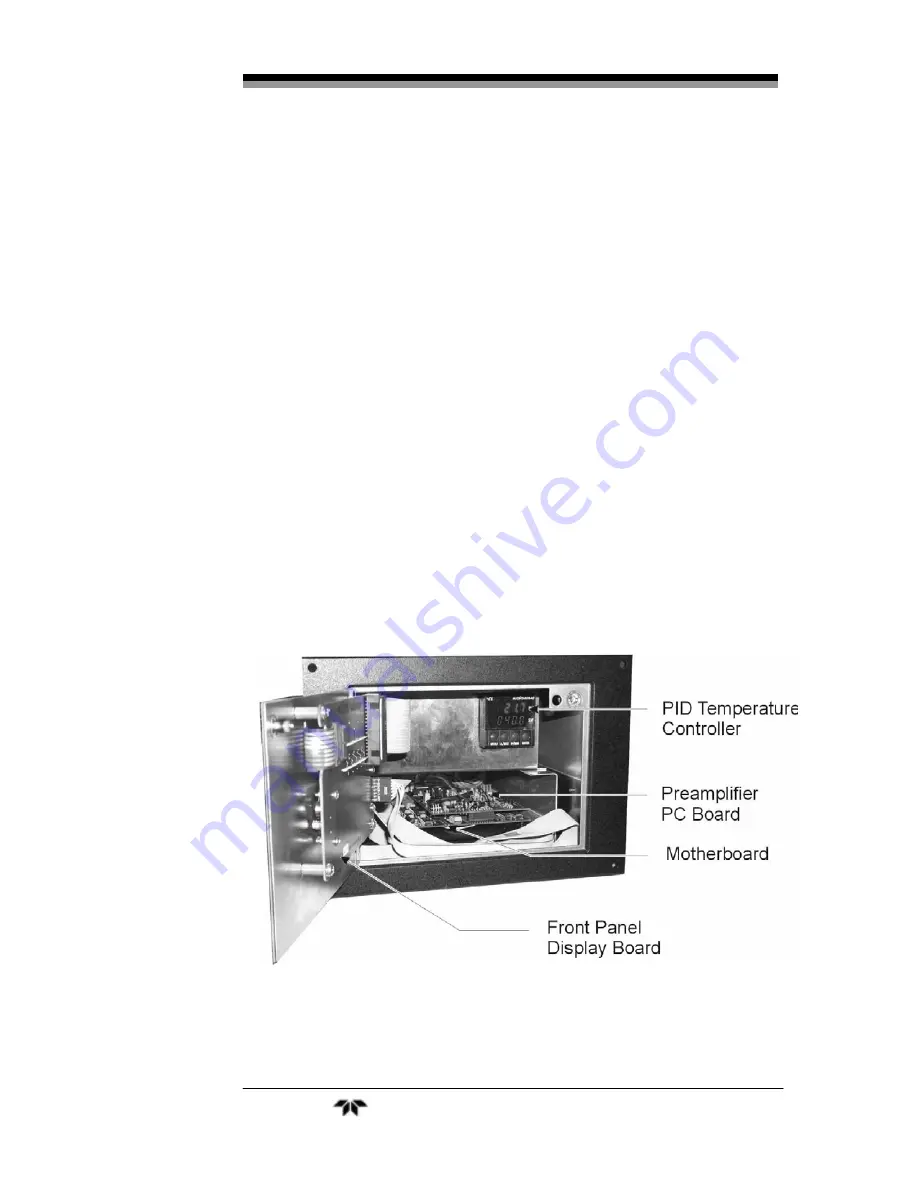

6.3 Oven and Temperature Controller

The oven in the Analysis Unit is used to provide thermal stability to

the sensor assembly is comprised of dual 40 watt heaters powered by 115

or 230 V ac from the Control Unit. The oven temperature is maintained at

40

°

C by a PID temperature controller housed in the Control Unit. An RTD

sensor is mounted in the Analysis Unit to provide feedback to the PID

controller. The temperature in the Analysis Unit at any time can be read

from the display on the temperature controller after opening the front

panel of the Control Unit. See Figure 6-5. This can be done without

affecting the thermal environment of the Analysis Unit.

Figure 6-5: Access to Temperature Controller in Control Unit

Summary of Contents for 3010MA

Page 12: ...Part 1 Control Unit Model 3010MA Teledyne Analytical Instruments xii...

Page 14: ...Part 1 Control Unit Model 3010MA Teledyne Analytical Instruments 14...

Page 24: ...Part 1 Control Unit Model 3010MA Teledyne Analytical Instruments 24...

Page 64: ...Part 1 Control Unit Model 3010MA Teledyne Analytical Instruments 64...

Page 66: ...Part 2 Analysis Unit Model 3010MA Teledyne Analytical Instruments 66...