5 Standard maintenance

The following operations have to be executed in the indicated times.

In case instructions will not be followed, the Manufacturer will be relieved from any

responsibility for the effects of Warranty.

Some of such operations, although easy, have to be done by Qualified Operators only.

IMPORTANT:

Operations indicated with the symbol (*) must be executed ONLY by Tecnoter's official

network.

Operations indicated with the symbol (!) are absolutely mandatory

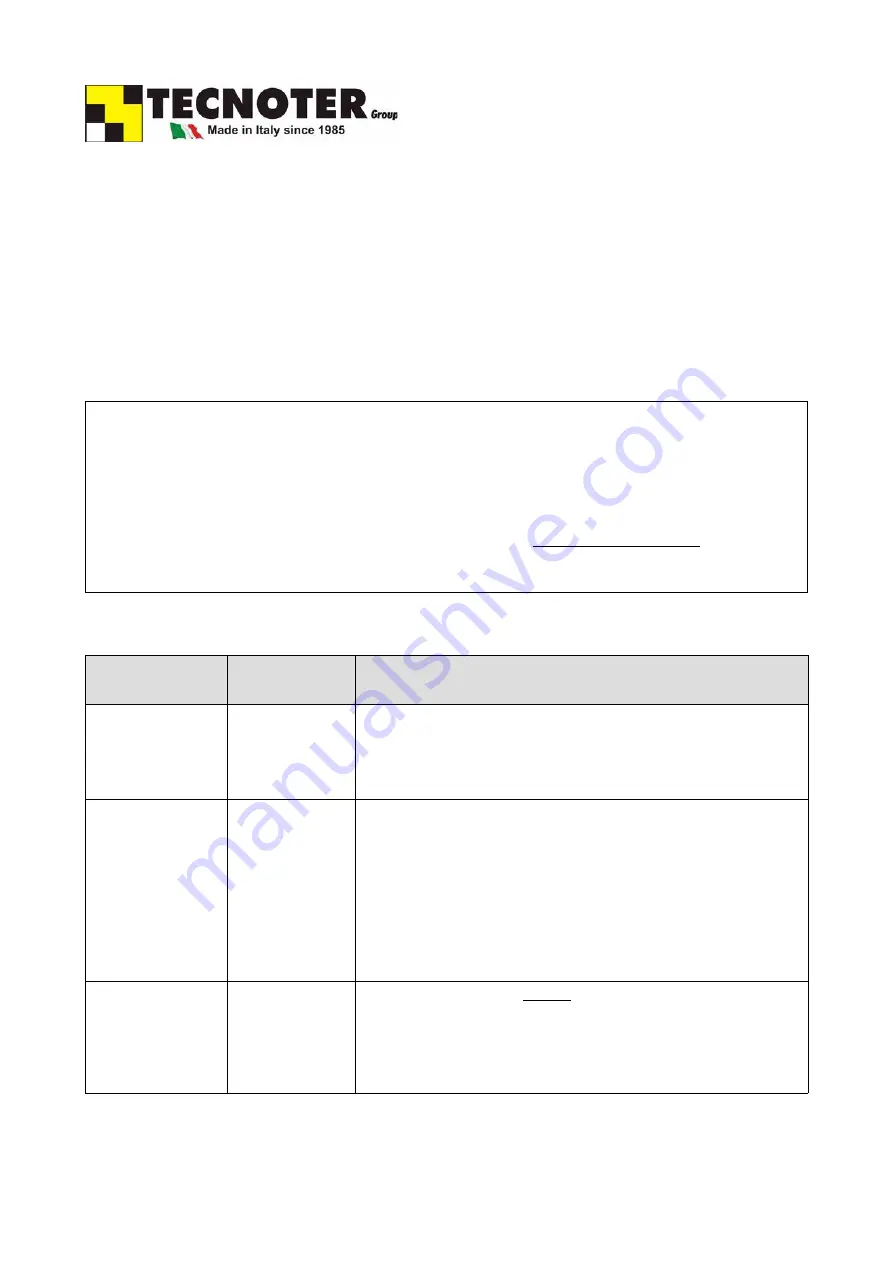

Programmed Maintenance Table:

Frequency

State of the

system

Inspection, maintenance

Every starting

In use

Visual and acoustic check of the correct functioning of each part of the

machine

Visual check of the cleaning of the washing lines

Visual check of the state of the washing fluid

Visual check of the structural integrity of the system

Daily

In use

Check the safety systems

Check the status of the oil absorbent and replace it when exhaust

Check level and quality of fluids

Clean the photoelectric sensor

Check system integrity

Removal of visible debris larger than 30 mm on their longer side

Visual check of leakages

Start a manual cycle pushing and holding the “manual cycle” button for

30 seconds and verify the correct function of each part with particular

attention to the correct functionality of the mud extractor

Every week

Isolated for

maintenance

Cleaning and lubrication with oil of extraction chain (!!)

Check condensation in the electric panel

Check the state of blades on the extraction chain, and replace them when

necessary

Tecnoter srl unipersonale

Wheel washing

system

RC4.32

E16CL4

S/N

Page 34/39

Rev: 1.42 –

22/02/2017