26

DIAGNOSTIC

The alarm condition is always signalled by

the buzzer (if present) and by the led of

The alarm icon

The alarm signal produced by a faulty

thermostat probe (probe 1) is shown as E1

on the instrument display.

When the sensor detects an error condi-

tion:

• the code E1 is displayed

•

the compressor is activated as indi-

cated by the "On" and "Off" para-

meters if

•

programmed for the duty cycle or:

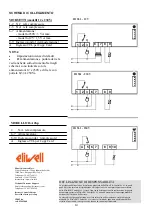

INSTALLATION

The instrument is designed for panel moun-

ting. Make a hole of 29x71 mm, insert the

instrument and fix it using the brackets

provided. Do not mount the instrument in

humid and/or dirty places; it is suitable for

use in ordinary polluted places. Ventilate

the place in proximity to the instrument

colling slits.

ELECTRICAL WIRING

Attention! Never work on electrical

connections when the machine is

switched on. The instrument is equipped

with screw terminal boards for connection

of electrical cables with a diameter of 2.5

mm2 (one conductor only per terminal for

power connections).For the capacity of

the terminals, see the label on the instru-

ment.The relay contacts are voltage free.

Do not exceed the maximum current allo-

wed; In case of higher loads, use an ap-

propriate contactor. Make sure the power

supplym voltage complies with the one

required by the instrument. In 12V

versions the power supply must be provi-

ded by a security transformer with the

protection of a delayed 250 mA fuse.

Probes have no connection polarity and

can be extended using a regular bipolar

cable (note that the extension of the

probes affects the EMC electromagnetic

compatibility of the instrument: pay

extreme attention to wiring).

Probe cables, power supply cables and

The TTL serial cables should be distant

from power cables.

CONDITIONS OF USE

PERMITTED USE

For safety reasons the instrument must

Be installed and used according to the

instruction provided and in particular,

under normal conditions, parts bearing

dangerous voltage levels must not be

accessible.

The device must be adequately protected

from water and dust as per the application

and must also only be accessible via the

use of tools (with the exception of the

frontlet).

The device is ideally suited for use on

household appliances and/or similar

refrigeration equipment and has been t

Ested with regard to the aspects concerni-

ne European reference standards on sa-

fety. It is classified as follows:

• according to its manufacture: as an

automatic electronic control device to be

incorporated by independent mounting;

• according to its automatic operating fea-

tures: as a 1 B-type operated control type;

as a Class A device in relation to the

category and structure of the software

UNPERMITTED USE

Any other use other than that permitted is

de facto prohibited. It should be noted

that the relay contacts provided are of a

practical type and therefore subject to

fault. Any protection devices required by

product standards or dictated by common

sense due to obvious safety reasons

should be applied externally.

LIABILITY ABD RESIDUAL

RISKS

Eliwell & Controlli s.r.l. shall not be liable

for any damages deriving from:

- installation/use other than that prescri-

bed and, in particular, that which does

not comply with safety standards anticipa-

ted by regulations and/or those given

herein;

- use on boards which do not guarantee

adequate protection against electric

shock,

water or dust under the conditions of

assembly applied;

- use on boards which allow access to

dangerous parts without the use of tools;

- tampering with and/or alteration of the

products;

- installation/use on boards that do not

comply with the standards and regula-

tions in force

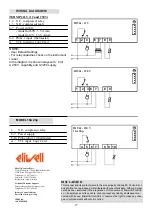

TECHNICAL DATA

Frontal panel protection: IP65.

Casing: plastic body in resin type

PC+ABS UL94 V-0, inspection window in

polycarbonate, buttons in thermoplastic

resin.

Dimensions: frontal panel 74x32 mm,

depth 60 mm.

Installation: on panel, with drilling tem-

plate 71x29 mm (+0.2/–0.1 mm).

PLEASE NOTE: The technical data

included in this document, related to

measurement (range, accuracy,

resolution, etc.) refer to the instru-

ment itself, and not to its equipment

such as, for example, sensors.This

means, for example, that sensor(s)

error(s) shall be added to the instru-

ment’s one.

Display

Error

Ont Oft Compressor output

0

0 OFF

0

>0 OFF

>0

0 ON

>0

>0

dc

MODEL 16A 2hp

Digital output: 1 N.O. relay SPST

16A 2hp; 250VA.

Consumption: 3 VA max.

Power supply: 230 Va ±10% 50/60 Hz.

*

NOTE 1

: Switch off and switch on again

the instrument after changing

the input type NTC/PTC (par. H00)

NOTE 2

: check the power supply specified

on the instrument label; for relay and

power supply capacities ( contact the

Sales Office).

Use temperature: –5…55 °C.

Storage temperature.: –30…85 °C.

Use environment humidity: 10…90 % RH

(not condensing).

Storage environment humidity: 10…90%

RH

(not condensing).

Viewing range: –50…99 without decimal

point on 2 digit + mark display.

Analog inputs: one PTC or NTC input

(selectable through parameter H00*).

Serial: TTL for connection to Copy Card.

Digital outputs: 1 relay contact

SPDT 8(3)A 250Va.

Measuring range: from –50 to 99 °C.

Accuracy: 0.5% better than end scale + 1

digit.

Resolution: 1°C.

Consumption:

• model 230V: 3 VA max.

• model 12V: 1,5 VA max.

Power supply: 12 Va/c ±10% or 230Va

±10% 50/60 Hz.

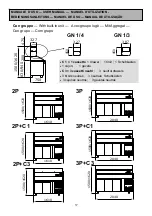

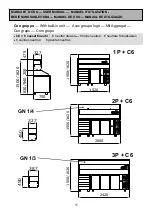

Summary of Contents for GN 1/3

Page 15: ...Note ...

Page 29: ...Note ...

Page 43: ...43 ...

Page 49: ...Note ...

Page 50: ...Note ...

Page 51: ...Note ...