22

USER AND MAINTENANCE MANUAL

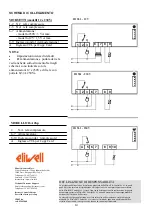

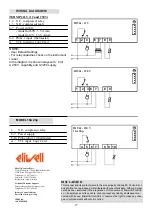

3_______ELECTRICAL CONNECTIONS AND GROUNDING CONNECTIONS

3_1_____POWER SUPPLY

The installation and electric connections must be carried out in a proper and workmanlike man-

ner in accordance with current electrical standards. These operations shall be conducted by

specialised qualified staff according to current regulations. The company will not be held liable

for the non-compliance of current electrical standards.

See the table unit’s wiring diagram.

Before powering the table unit, clean the refrigerated table thoroughly

using warm water and non-aggressive neutral de-

tergents, dry all wet parts using a soft cloth

(warning: read the cleaning instructions of the table unit very carefully).

In order to connect the unit adequately proceed as follows:

•

prearrange a differential thermo-magnetic switch

and make sure the frequency/voltage line corresponds with the one

indicated on the

refrigerated table’s identification plate (see plate positioning)

•

make sure the power voltage at the point of delivery

is +-10% upon starting the compressor.

•

it is advisable to mount a power supply bipolar main switch (or polar board)

with opening contacts of at least 3

mm, upstream from the socket. This main switch is mandatory when load exceeds 1000 watts or when the refrigerated

table is connected directly without using a plug. The thermo-magnetic switch must be positioned within immediate prox-

imity to the table unit so that it can be clearly visible by technicians in case of maintenance.

The diameter of the power cable must be appropriate for the power consumed by the unit.

•

The unit must have a grounding connection by law,

therefore it must be connected to an efficient grounding system.

In order to prevent any risks, if the power cable is damaged, it must be replaced by specialised qualified techni-

cians.

It is also recommended not to use electrical devices inside the table unit's compartments.

•

In order to prevent any risks, if the compressor is damaged, it must be replaced exclusively by quali-

fied technicians.

It is advisable to use a highly sensible differential thermo-magnetic switch as disconnecting

switch to avoid disconnecting the entire system in the event of a fault.

3_2______STARTING THE REFRIGERATED TABLE

Make sure to check the following before starting the refrigerated table:

•

the refrigerated table fitted with built-in condenser must be transported solely in vertical position, if it is tilted,

make sure to wait at least 8 hours before starting the unit;

this time will allow the oil on the compressor to flow into

all of its components, lubricating all parts once again.

•

In order to adjust operating parameters consult the information on the electrical control board section in the

user instructions enclosed herein.

•

for refrigerated tables with built-in units

make sure that the disconnecting switch is open, in position 0, OFF or green,

before connecting the plug into the power socket, then connect the plug and close the switch.

•

Avoid setting temperatures lower than the table unit’s relative temperature.

•

the first startup operation for refrigerated tables or for remote units must be performed by qualified staff.

Once the power line is connected to the refrigerated table (see previous paragraph), power the unit by closing the

switch.

Warning: before loading goods on the table unit, make sure that the temperature reaches the desired temperature set

on the control panel. Avoid setting temperatures lower than the table unit’s relative temperature; this could obstruct

the evaporation process.

EN

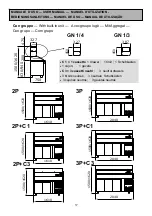

Summary of Contents for GN 1/3

Page 15: ...Note ...

Page 29: ...Note ...

Page 43: ...43 ...

Page 49: ...Note ...

Page 50: ...Note ...

Page 51: ...Note ...