7

5.5 - STARTING

• Initial condition:

- Machine hydraulically and electrically connected ready to operate.

- Operating mode remote changeover switch is in required position (heating or cooling).

- The remote On/Off contact is open (off).

• Turn the installation on.

• The display comes on and shows the water temperature (read by the control probe S1).

• Close the possible remote on/off contact (not supplied) if it is not connected (see paragraph 4.2.3).

• The indicator lamp corresponding to the selected mode lights up:

- indicator lamp (7) : Cooling,

- indicator lamp (8) : Heating.

• The compressor "ON" indicator light (6) comes on if necessary (see diagram paragraph 5.4). If the light flashes, it means that

the compressor is starting required but that a safety delay is in progress. This light stays on when the compressor has started.

• To stop the unit, open the remote On/Off contact (in this case, restart is automatic as soon as this contact is closed).

The operating mode indicator lights (7) and (8) and the compressor operation light (6) go off.

PRG

mute

SEL

µ

chiller

5 sec

CAUTION: Changing the operating mode (heating/cooling) must only be done when the machine is stopped.

• It is possible to stop and restart the current mode (selected remotely) by pressing the

▲

key

(2) for the cooling mode or the

▼

key (3) for the heating mode.

NOTE:

The controller’s anti-short cycle system requires that the compressor operate for a minimum

amount of time. If the machine should stop, the compressor may continue to function for a certain

amount of time (150 seconds max.).

PRG

mute

SEL

µ

chiller

5 sec

comp

x 100

PRG

mute

SEL

µchiller

the PRG (1) key. If during the adjustment procedure no key is pressed for 60 seconds (this period is indicated by the display

flashing), the system automatically reverts to normal operation and display without storing the latest parameter changes.

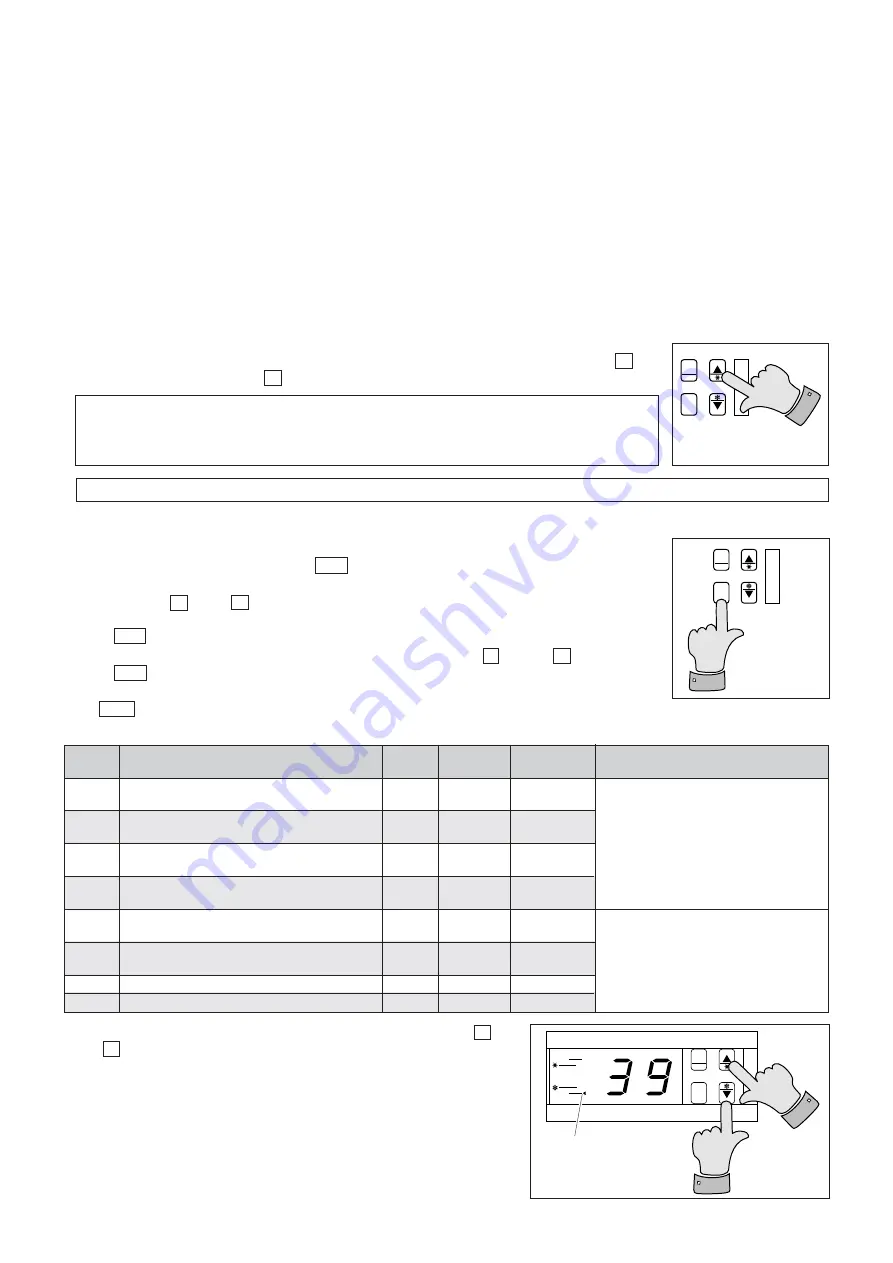

5.6 - ADJUSTING AND DISPLAYING THE PARAMETERS

• Parameters accessible by pressing the SEL (4) key for 5 seconds.

• The display displays the code of the 1st parameter on the list ("r1" - see below).

• By pressing the

▲

(2) or

▼

(3) keys, scroll through the parameter codes until you reach the one

you want.

• Press SEL (4) to find out the value of the corresponding parameter.

• The value of the parameter can if necessary be changed using the

▲

(2) and

▼

(3) keys.

• Press SEL (4) to re-display the parameter codes.

• To store the parameters which have been changed and to exit the adjustment procedure, press

Code

Parameters

Factory

setting

Installation

setting

Adjustment

range

22

°

C

2 k

35

°

C

2 k

-

-

-

-

-

-

-

-

Probe located on water return

Set point

Cooling ("Summer")

Differential

Cooling

Set point

Heating ("Winter")

Differential

Heating

Water heat exchanger temperature

(Probe S2 for anti-freeze)

Air heat exchanger temperature

(Probe S3)

Compressor hour meter

Pump hour meter

r 1

r 2

r 3

r 4

r 6

r 8

c 9

c C

Display only

10 to 30

°

C

0.3 to 19.9 k

25 to 45

°

C

0.3 to 19.9 k

-

-

-

-

Remarks

• The hour meters are zeroed by pressing simultaneously on the

▲

(2)

and

▼

(3) keys.

• Note:

The configuration and parameterization of each machine are factory-

set for optimal "Cooling/Heating Floor" operation.

If light (9) is on,

multiply the time

displayed by 100.