- 4 -

1- Before turning the power ON

b)

About power source

Do not use any other outlet than followig.

Do not connect more than one equipments

onto one outlet.

Otherwise, it may cause

a fire and/or electric shock.The specified

rating of this equipment is following.

100 ‘240 VAC

2A

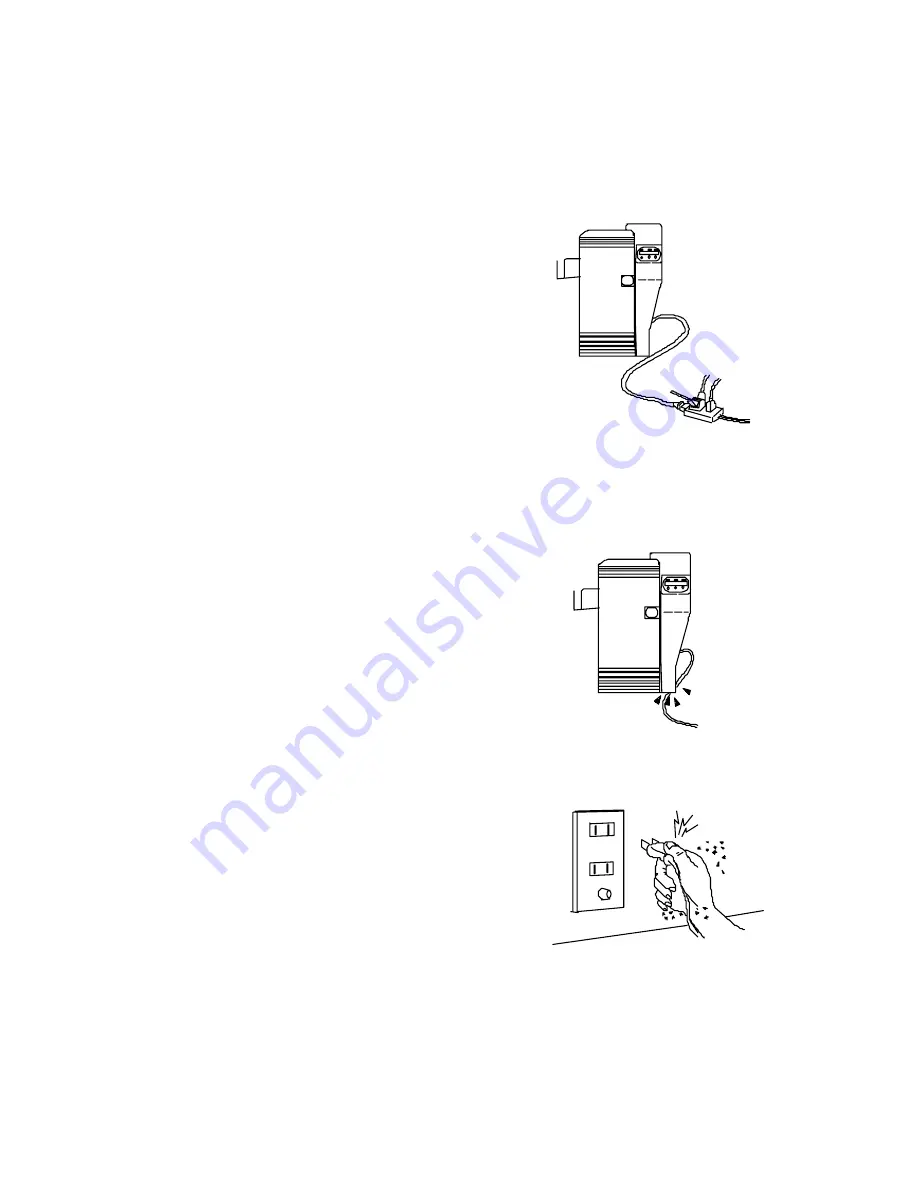

Dust on the plug and electrical outlet mustbe removed.If used without

removing, a small amount of electricity runs continuously through the dust

by the effect of moisture etc. and may eventually cause a fire.

Be careful so that the power supply cord

is not damaged.

If the cord is twisted,

pulled strongly or placed underneath a

heavy object, it may be damaged and become

a cause of fire.

Do not handle the plug with wet hand

because it may cause electric shock.

When you use an extention cord, do not use the cord which is rated at less

than 125V 10A.

Excessive heat or smoke will be caused.

Summary of Contents for Nisca PR5300

Page 1: ...DIRECT CARD PRINTER PR5300 Operation Manual Ver 1 3 Aug 00...

Page 46: ...44 A...

Page 53: ...51 Block Layout...