13.5 Gearbox

After 50 hours of use the gear box oil should be drained

and replaced with new oil. To drain the oil, remove the

PTO shaft and guard cone remove the drain and filler

plugs and allow it to empty. Waste oil should be

collected and disposed of at an oil recycling facility

Refill the gearbox to the level plug with SAE90.EP

gearbox oil. The oil capacity of the gearbox is 4.7ltrs

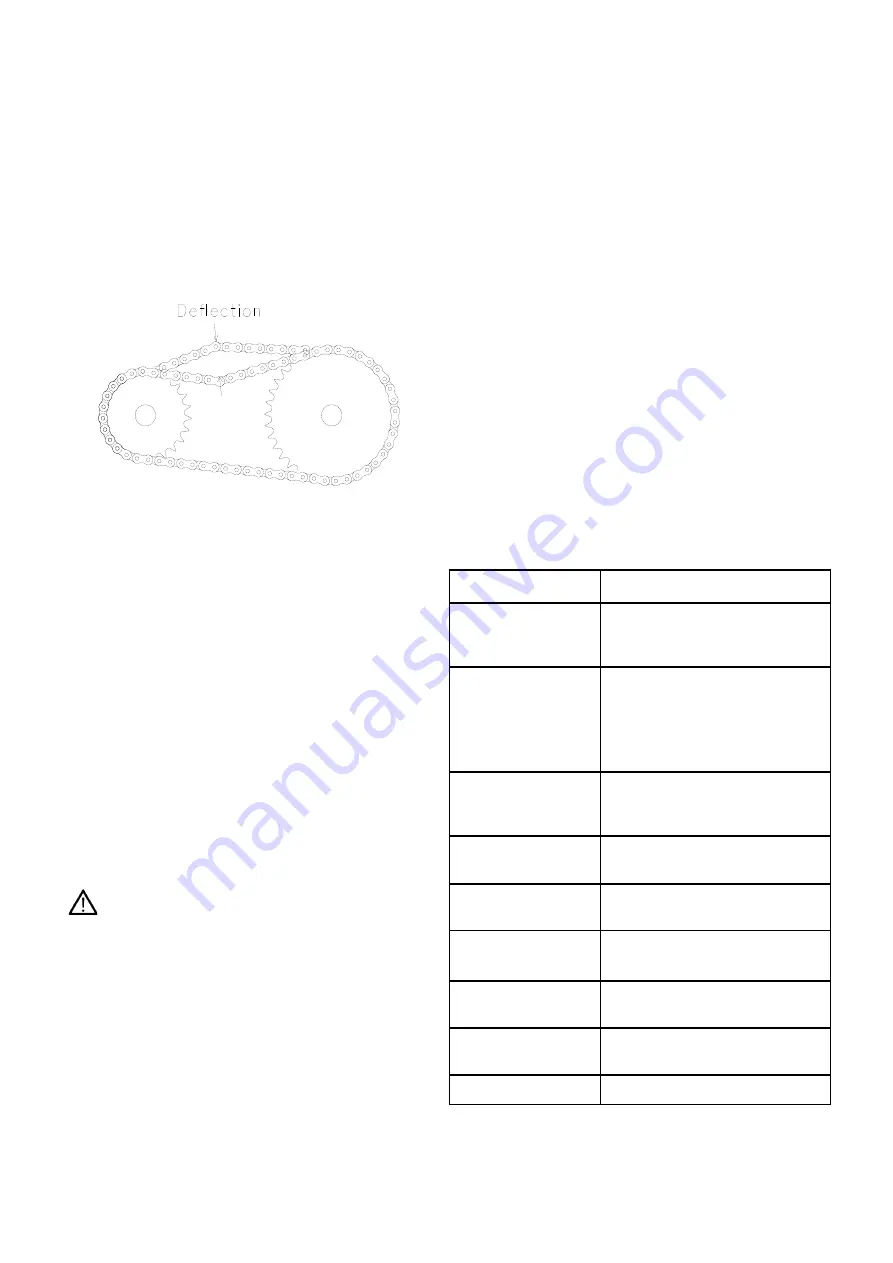

13.6 Drive Chains

Apply chain lubricant or oil weekly. The chains should be

tensioned so that there is 12-13mm (1/2”) deflection at

the mid span point as indicated in figure 7 below.

Figure 7. Chain Deflection

To tension the crossbeaters drive chains, open the

hinged chain guard on the left hand side of the

machine

.

For the lower beater drive, slacken the

layshaft bearing bolts and tensioner locknut. Increase

tension by jacking the bearing as required until the

correct tension condition is met. Retighten all nuts. For

the upper crossbeater slacken the tensioner roller

mounting bolt in the centre of the roller and turn the

tension screw on the adjuster clockwise until the

correct tension condition is met. Retighten the roller

mounting bolt.

13.7 Swivel Chute

The chute is rotated by means of a gear and ring gear.

It is important that this is well greased. To apply grease

to the ring gears there are 4 grease nipples on the

mounting flange.

The deflector ram has 2 grease nipples, one on each

pivot bush.

13.8 Hydraulics

Before attempting to dismantle any of the hydraulic

system, the tailgate and deflectors must be fully

lowered to prevent injury from the unexpected lowering

of these components.

The hydraulic system is protected from contamination by

an inline pressure filter. Periodically the element should

be checked for contamination and it is recommended

that the element be replaced at least once annually. To

replace the element, remove the guard covering the

hydraulic valve on the front right of the machine and

unscrew the filter canister. Replace element, retighten

canister and fit valve guard.

If problems are experienced with either the hydraulic

system or electric controls, please contact Teagle

Machinery Ltd. for advice as a separate manual is

available to cover troubleshooting and repair.

13.9 PTO Slip Clutch

If the clutch slips repeatedly for no apparent reason

there are a number of things to be checked:

Firstly check that the clutch linings do not show signs of

damage or excessive wear. If so, they should be

replaced. When new they are 3mm. (1/8") thick.

Also make sure that the compressed spring length is set

to give the correct torque setting – see PTO shaft parts

list.

If the clutch continues to slip it should be adjusted as

follows:

1 Remove the guard fitted to the rotor gearbox.

2 Fit the PTO shaft with the slip clutch at the machine

end.

3 Insert a piece of wood through the discharge chute

and position it such that it prevents the rotor from

turning.

4 Insert a steel bar through the rear PTO yoke and use

a spring balance to obtain the correct torque setting.

The clutch should just slip at a torque of 1200 Nm.

(900 lb.ft.) - equal to a force of 1000N. at 1.2 metre

(225 lb. at 4 feet) from the centre of the yoke. Adjust

the clutch as necessary using the eight spring loaded

clamp bolts.

13.10 Lubrication

Good quality semi-solid grease should be applied to the

following grease points:

The above lubrication frequencies are based on typical

daily use for bedding & feeding purposes. Continuous

use for special applications may require more frequent

lubrication.

9

Greasing / Oil

See separate Chart

PTO and clutch

Lubricate as Chart

Dismantle Clutch at Start of

Season

Gearboxes

Replace main gearbox oil after

first 50 hours then check

monthly. Where fitted, check

bed chain drive gearbox

monthly

Remove stones

Each Bale Or Daily,

Depending On Use And Na-

ture Of Bales

Bed Chain

Tension

After First Day Then

Weekly Depending On Use

Crossbeater Chain

Tension

Weekly

Clean above

inspection Panel

Monthly, Depending On Use

Tyre pressures &

Wheel nuts

Monthly

Option – Replace

oil filter

Yearly

Blades

As Required

Summary of Contents for Tomahawk 1010

Page 1: ......

Page 38: ...34 HYDRAULIC HOSES...

Page 43: ...WIRING DIAGRAM LIGHTS WIRING DIAGRAM TRACTOR LEAD 39...

Page 44: ......