408-32027

3 of 11

Rev A

The front guard has been modified to remove the

guard insert. The front guard works together with the

applicator guarding to protect the operator. The front

guard retains its keyed interlock to actuate the guard

safety switch when closed.

The modified guards on the AMP 5K/40 CE through-

slice terminator will work with side-feed and end-feed

CE through-splice applicators.

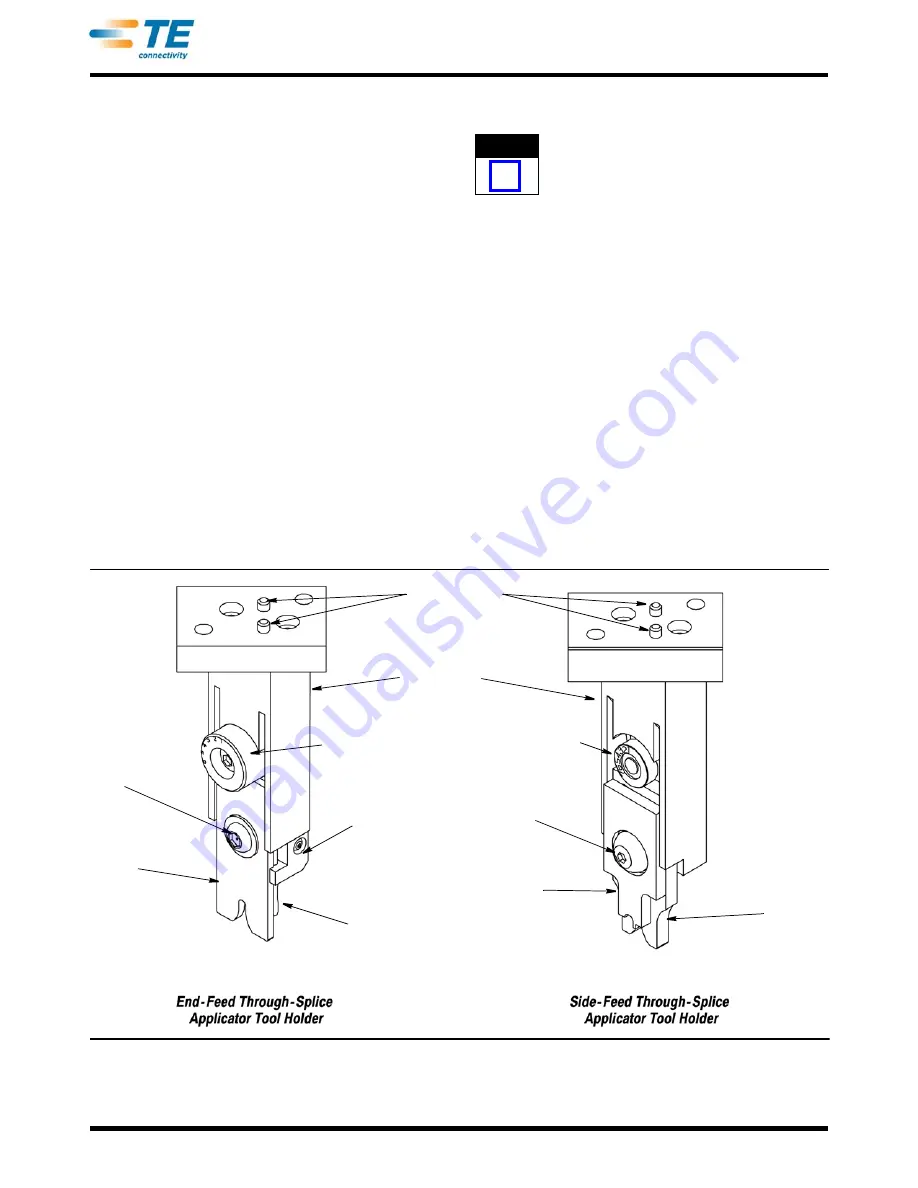

2.2. Applicator Description

End-Feed and Side-Feed applicators used with AMP

5K/40 CE through-splice terminators are two-piece

applicators consisting of a tool holder and applicator

base.

The tool holder is secured to the ram of the AMP

5K’/40 Through-Splice Terminating Machine with two

screws. The tool holder contains locating pins

(Figure 4) to facilitate it's location on the terminator

ram. The locating pins allow an easier tooling

changeover.

The wire crimper, insulation crimper, and the front

shear depressor are located in a pocket in the tool

holder, and are secured by a crimper bolt. The front

shear depressor pushes the front floating shear down

to cut the crimped terminal from the strip.

The wire crimp is easily adjusted, providing an array of

different wire crimp sizes.

NOTE

i

All AMP 5K/40 CE Through-Splice Terminators are

equipped with a "precision adjust" feature.

The hold-down bracket (see Figure 4) is attached to

the ram and, with bracket attached, holds the terminal

in place during the crimping and shearing process.

The applicator's mounting surface is its base plate.

The base plate attaches to the base of the terminator.

The anvil, shear tooling and strip guide plates are all

located on the base plate.

Since the upper tooling is permanently located, the

lower tooling can be adjusted to the correct position

and locked (screwed) into place.

End-Feed and Side-Feed Through-Splice Applicators

can withstand the high crimping pressures required to

apply terminals to the larger CMA ranges (up to

approximately 17,000 CMA ). Although these

applicators accept only certain terminals, they provide

valuable application flexibility. The design optimizes

accessibility which aids in more precise wire

placement, and increased production throughout.

Locating Pins

Tool Holder

Crimp Height

Adjustment Wheel

Hold-Down

Bracket

Shear Blade

Crimper

Bolt

Wire

Crimper

Front Shear

Depressor

Crimp Height

Adjustment Wheel

Wire

Crimper

Crimper

Bolt

Figure 4