408-32027

4 of 11

Rev A

Terminal strip is fed into the applicator with the barrel

(wire) end first, between the front (outer) and rear

(inner) strip guides. It passes the stock drag, and the

LEAD terminal is positioned over the anvil. The feed

pawl feeds one terminal during each cycle of the

machine. The terminals are fed by the action of the air

cylinder that is controlled by a valve on the terminator.

NOTE

i

Some applicators have a solid metal hold-down

that may require adjustment when changing the

wire size and/or crimp height.

Terminals with dual-carrier strips require a shear

depressor, spacer, and terminal holder. These parts

are also attached to the tool holder assembly. The rear

shear depressor pushes the rear floating shear down

to cut the terminal from the rear carrier strip, and the

terminal holder keeps the terminal from raising during

the crimping and shearing process.

The anvil, the front shear holder, the rear shear holder

(if used), the terminal support, and the strip guide

adjustment block are mounted on the base plate, as

well as the rear floating shear and rear shear holder.

The strip guide plate (Figure 5) is fastened to the strip

guide adjustment block. The stock drag, the strip

guide cover plate, and the front and rear strip guides

are mounted on the strip guide plate.

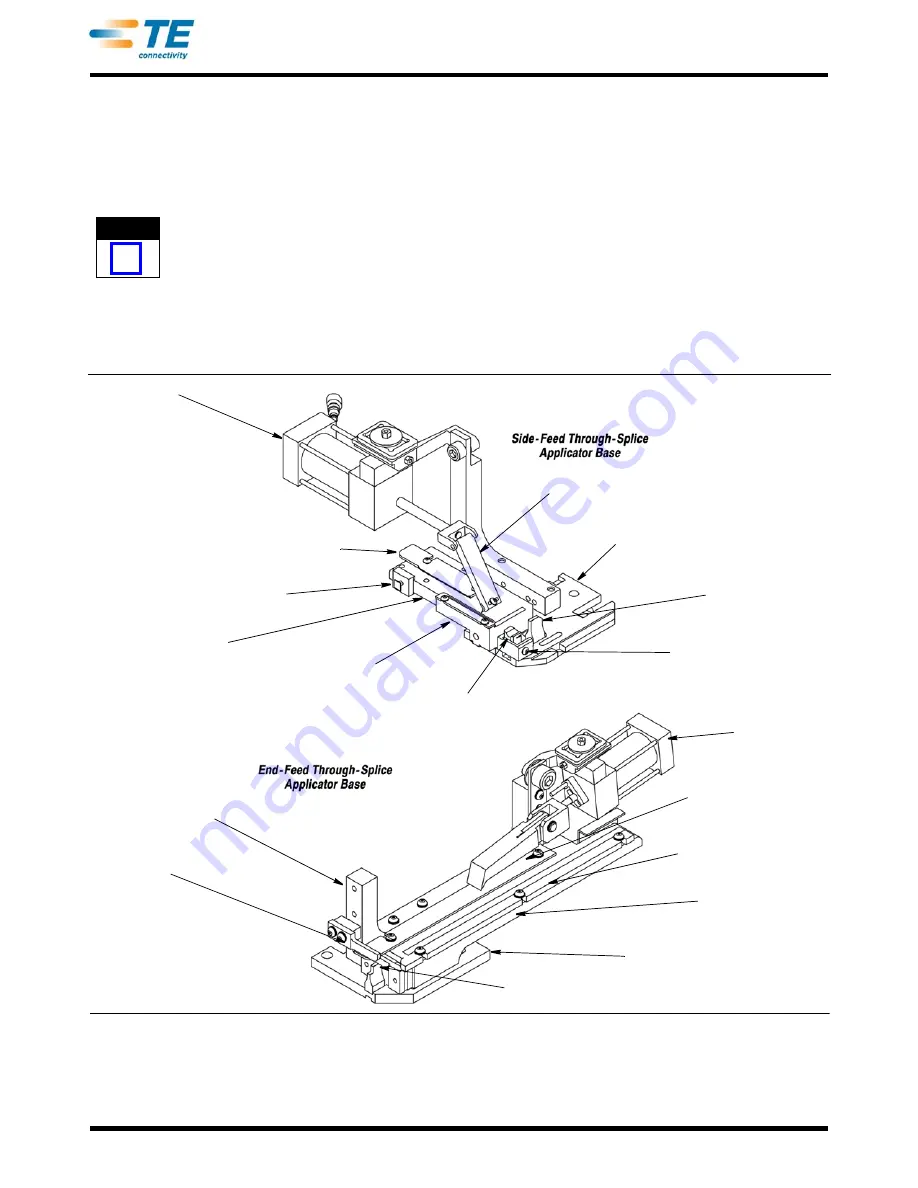

The applicators used for the through-splice application

are PRE-FEED Applicators. This means that the lead

terminal is over the anvil when the machine is at rest.

Feed Cylinder

Front Strip Guide

Strip Guide Plate

Strip Guide

Adjusting Block

Terminal Drag

Shear Retaining Screw

Anvil

Applicator

Base Plate

Feed Finger

Feed Bracket

Stripper

Anvil

Applicator

Base Plate

Strip Guide Plate

Front Strip Guide

Rear Strip Guide

Floating Shear

Feed Finger

Feed Cylinder

Figure 5