OPERATING PROCEDURES

6-5

Model C723

Operating Procedures

6

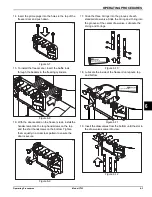

26. Slide two O-rings into one end of the feed tube. Slide

two O-rings on the other end of the feed tube.

Figure 6-18

27. Slide the small O-ring into the groove of the air

orifice.

Do not

lubricate the O-ring.

Figure 6-19

Note:

Make sure the hole in the air orifice is clean and

is not clogged. If the hole in the air orifice should become

clogged, use soap and hot water to clear the hole.

Do

not

enlarge the hole in the air orifice.

28. Install the air orifice into the hole in the top of the feed

tube (the end of the feed tube without the small hole

on the side).

Figure 6-20

29. Lay the feed tube (with air orifice installed) and the

agitator (factory-equipped agitator machines only) in

the bottom of the mix hopper for sanitizing.

30. Repeat steps 26 through 29 for the other side of the

machine.

Sanitizing

1. Prepare an approved 100 ppm sanitizing solution

(examples: 2-1/2 gal. [9.5 L] of Kay-5® or 2 gal.

[7.6 L] of Stera-Sheen®). Use warm water and follow

the manufacturer's specifications.

2. Pour the sanitizing solution over all the parts in the

bottom of the mix hopper and allow it to flow into the

freezing cylinder.

Figure 6-21

Note:

You have just sanitized the mix hopper and parts.

Therefore, make sure your hands are clean and

sanitized before proceeding to the next step.

12076

12077

12078

12029

Summary of Contents for C723

Page 14: ...3 4 SAFETY Model C723 Safety 3 Notes ...

Page 42: ...6 10 OPERATING PROCEDURES Model C723 Operating Procedures 6 Notes ...

Page 48: ...9 2 PARTS REPLACEMENT SCHEDULE Model C723 Parts Replacement Schedule 9 Notes ...

Page 52: ...10 4 LIMITED WARRANTY ON EQUIPMENT Model C723 Limited Warranty on Equipment 10 Notes ...

Page 56: ...11 4 LIMITED WARRANTY ON PARTS Model C723 Limited Warranty on Parts 11 Notes ...