20

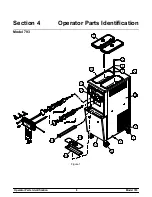

Model 793

Operating Procedures

Priming

Step 1

With a pail beneath the door spouts, lower the

center and side draw handle. Pour two gallons (7.6

liters) of fresh mix into the mix hopper and allow it to

flow into the freezing cylinder. This will force out any

remaining sanitizing solution. When full strength mix

is flowing from the door spouts, raise the draw

handles.

Note:

Use only

fresh

mix when priming the freezing

cylinder.

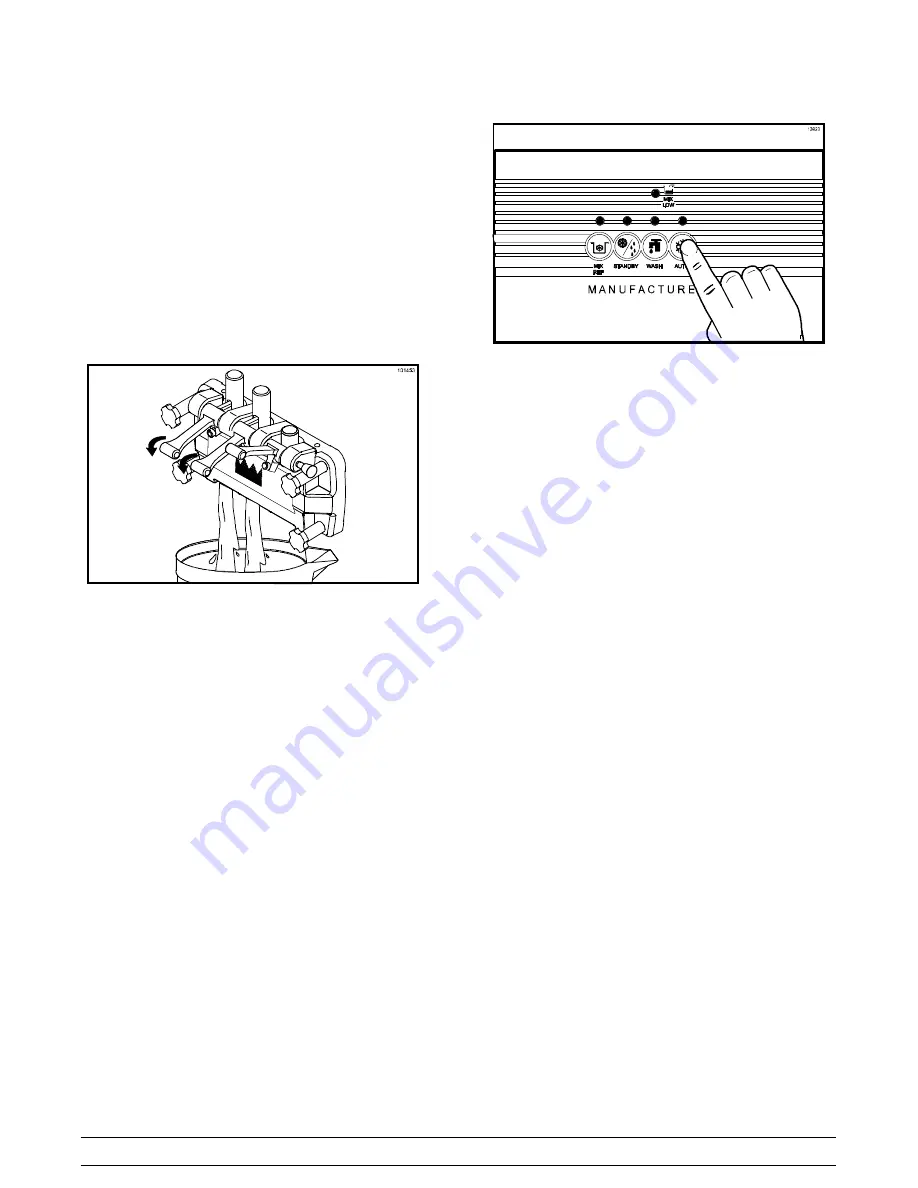

Figure 26

Step 2

Lubricate the o-rings on the end of the air tube that

has a small hole on the side.

Step 3

Install the air tube (end with hole on the side) into

the mix inlet hole in the mix hopper.

Step 4

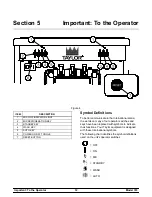

Press the AUTO key. The AUTO light will come on

indicating that the main refrigeration system is

operating. When the unit cycles off, the product will

be at serving viscosity. The MIX REF light will come

on, indicating the mix refrigeration system is

operating to maintain the mix in the mix hopper.

Figure 27

Step 5

Fill the hopper with mix. As the mix level comes in

contact with the mix level sensing probe on the rear

wall of the hopper, the MIX LOW light will shut off.

Step 6

Place the mix hopper cover in position over the mix

hopper.

Repeat steps 1 - 6 for the other side of the unit.

Closing Procedure

At the close of business, all product must be drained

from the mix hoppers and the freezing cylinders and

the unit must be rinsed, cleaned, disassembled, and

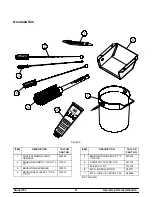

brush cleaned. The following items will be needed:

S

Two cleaning pails

S

Sanitized stainless steel rerun can with lid

S

Necessary brushes provided with unit (see

page 11)

S

Approved cleaning/sanitizing solution with

active chlorine concentrate of 100 - 200

PPM

S

Single service towels

Summary of Contents for 793

Page 47: ...Model 793 082065 33 Rev 6 13...