Handling the Container

The XL Series containers are very rugged liquid cylinders. All cryogenic liquid cylinders

have an inner container and an outer container with an insulated vacuum space between

them. Any abuse (dents, dropping, tip-over, etc.) can affect the integrity of the containers

insulation system.

When fully loaded, the XL-55 in argon service will contain 551 lb. (250 kg) of product.

While moving a full container, you may be handling 821 lb. (372 kg) and you should treat

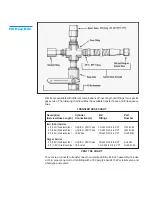

the load accordingly. The attachment points provided on the XL-45/50/55 will allow you to

use a hand truck or a hoist to handle these loads properly. Do not attempt to move these

cylinders by any other means. While moving the cylinder, the following precautions should

be observed.

q

Never lay the cylinder on its side. Always ship, operate and store the unit in a vertical

or upright position.

q

When loading or unloading the container from a truck, use a hand truck, lift gate, crane

or parallel loading dock. Never attempt to manually lift the unit.

q

To move the container over rough surfaces, or to lift the container, attach an appropri-

ated sling to the lifting points cut into the welded support posts, and use a portable

lifting device that will handle the weight of the container and its contents.

XL-45, XL-50, XL-55

Containers

FREIGHT DAMAGE

PRECAUTIONS

ANY FREIGHT DAMAGE CLAIMS ARE

YOUR RESPONSIBILITY. Cryogenic

liquid containers are delivered to your

carrier from Taylor-Wharton’s dock in new

condition. When you receive our product

you may expect it to be in that same

condition. For your own protection, take

time to visually inspect each shipment in

the presence of the carrier’s agent before

you accept delivery. If any damage is

observed, make an appropriate notation

on the freight bill. Then ask the driver to

sign the notation before you receive the

equipment. You should decline to accept

containers that show damage which may

affect serviceability.