Index

Recommended

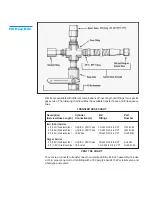

No.

Description

Part No.

For 10 Units

1.

Dual Regulator, Pressure Building/Economizer

69999-9015

2 Each

125 psig (8.6 bar/862 kPa)

* 2.

Gasket, Glass Filled Teflon, Contents Gauge

7701-0083

5 Each

3.

Contents Gauge Assembly (Includes Gauge and Spring)

GL45-9C65

1 Each

* Float Rod (45/50)

GL45-9C96

1 Each

(55)

GL45-9C97

1 Each

4.

Contents Gauge Cover, Protective Clear

GL50-9C54

4 Each

Snap-on indicator, Nitrogen

GL45-9C75

4 Each

Snap-on indicator, Oxygen

GL45-9C77

4 Each

Snap-on indicator, Argon

GL45-9C76

4 Each

5.

Screw, Brass, 1/4 in. - 20 UNC x 5/8 in.

6114-1088

10 Each

5a.

Washer, Lock, 1/4 in., Stainless Steel

6460-2025

10 Each

6.

Gauge, Pressure 0-400 psig (0-28 bar/0-2758 kPa)

7702-6196

2 Each

7.

Safety Head 380 psig (26 bar/2620 kPa)

1190-9C21

2 Each

8.

Relief Valve

**22 psig (1.5 bar/152 kPa)

6913-9069

5 Each

230 psig (16 bar/1586 kPa)

6913-9070

5 Each

9.

Valve Repair Kit

1750-9C35

3 Each

10.

Elbow, Male, Brass 45

°

3/8 in. ODT-comp x 1/4 in.

6814-9233

2 Each

11.

Connector, Lake, Brass, 3/8 in. ODT-comp x 1/4 in. NPT-EXT

4570-1960

2 Each

12.

Tube, P.B./Economizer Line

GL45-9C20

2 Each

14.

Elbow, Male, 3/8 in. NPT x 1/4 in. NPT 45

°

6814-9241

2 Each

End Fittings for Hand Valves

15.

-USE (CGA 540)-oxygen

7114-0163

5 Each

-USE (CGA 580)-argon/nitrogen

7114-0164

5 Each

-USE (CGA 320)-carbon dioxide

7114-0181

5 Each

-USE (CGA 326)-nitrous oxide

7114-0195

5 Each

16.

-LIQUID (CGA 440)-oxygen

6514-8992

5 Each

-LIQUID (CGA 295)-argon/nitrogen

7355-4712

5 Each

-LIQUID (CGA 320)-carbon dioxide

7114-0181

10 Each

-LIQUID (CGA 326)-nitrous oxide

7114-0195

10 Each

17.

-VENT (CGA 440)-oxygen

6514-8992

5 Each

-VENT (CGA 295)-argon/nitrogen

7355-4712

5 Each

-VENT (CGA 295)-carbon dioxide

7355-4712

5 Each

-VENT (CGA 295)-nitrous oxide

7355-4712

5 Each

*

Decal, Warning

1700-9C07

4 Each

*

Decal, Nitrogen

GL55-9C51

A/R

*

Decal, Oxygen

GL55-9C52

A/R

*

Decal, Argon

GL55-9C53

A/R

*

Decal, UN Number, Nitrogen

GL55-9C63

A/R

*

Decal, UN Number, Oxygen

GL55-9C64

A/R

*

Decal, UN Number, Argon

GL55-9C65

A/R

* Not illustrated.

** Optional/Not Illustrated.