NOTE:

For detailed

information on the

handling of cryogenic

liquids, refer to the

Compressed Gas

Association

publication: P-12

“Safe Handling of

Cryogenic Liquids”

available from the

Compressed Gas

Association, Inc., 1235

Jefferson Davis

Highway, Arlington,

VA 22202.

Pressure Hazard -

The containers covered by this literature may contain pressures up

to 230 psig (16 bar/1586 kPa.) Sudden release of this pressure may cause personal injury

by issuing cold gas or liquid, or by expelling parts during servicing. Do not attempt any

repairs on these containers until all pressure is released, and the contents have been

allowed to vaporize to ensure no pressure build-up can occur.

Extreme Cold – Cover Eyes and Exposed Skin –

Accidental contact of the skin or

eyes with any cryogenic liquid or cold issuing gas may cause a freezing injury similar to

frostbite. Protect your eyes and cover your skin when handling the container or transfer-

ring liquid, or in any instance where the possibility of contact with liquid, cold pipes, and

cold gas may exist. Safety goggles or a face shield should be worn when withdrawing

liquid or gas. Long-sleeved clothing and gloves that can be easily removed are recom-

mended for skin protection. Cryogenic liquids are extremely cold and will be at tempera-

tures below -300° F (-184°C) under normal atmospheric pressure.

Keep Equipment Well Ventilated –

Although some of the gases used in these contain-

ers are non-toxic and non-flammable, they can cause asphyxiation in a confined area

without adequate ventilation. An atmosphere that does not contain enough oxygen for

breathing will cause dizziness, unconsciousness, or even death. These gases cannot be

detected by the human senses and will be inhaled normally as if they were air. Ensure

there is adequate ventilation where these gases are used and store liquid containers or

only in a well ventilated area.

Replacement Parts Must be “Cleaned for Oxygen Use” –

Some materials, espe-

cially non-metallic gaskets and seals, can be a combustion hazard if used in oxygen or

nitrous oxide service, although they may be acceptable for use with other cryogenic

liquids. Use only Taylor-Wharton recommended spare parts, and be certain parts used on

oxygen or nitrous oxide are marked “cleaned for oxygen service.” For information on

cleaning, consult the Compressed Gas Association (CGA) pamphlet G-4.1, “Cleaning for

Oxygen Service” or equivalent industrial cleaning specifications.

Install Relief Valves in Cryogenic Liquid Lines –

When installing piping or fill hose

assembly, make certain a suitable safety relief valve is installed in each section of plumb-

ing between shut off valves. Trapped liquefied gas will expand as it warms and may burst

hoses or piping causing damage or personal injury.

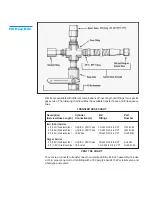

The XL-45, XL-50 and XL-55 are vacuum insulated, stainless steel containers designed to

store and transport cryogenic liquid oxygen, nitrogen or argon. Built to DOT 4L standards,

these containers may be used for over the road transportation of cryogenic fluids, as well

as on-site storage and supply in a wide range of applications.

As rugged, long holding time, self-contained gas supply systems, these cylinders are

capable of providing continuous flow rates of up to 350 cfh (9.2 cu.m/h) with a delivery

pressure of approximately 100 psig (6.9 bar/690 kPa).

CONTAINER

SAFETY

GENERAL

INFORMATION