LUXE

13

ENGLISH

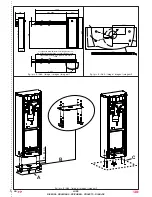

3.3_ Typical system (pic. # 11)

1 Luxe cabinet

2 Control panel

3 Aluminium bar

4 LED strip

5 Bar gasket

6 LED display

7 Aerial

8 Photocell pillar

9 Photocells

10 Photocell side support

11 Bar rest (fixed)

12 Metal mass sensor

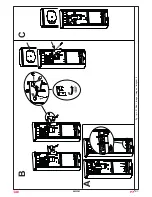

3.4_ Automation base preparation

Wall the foundation plate so that the barrier door and

the releasing handle are easy to access.

Create a rectangular, suitably sized floor slab (A pic. # 3) with the

holes for the exiting cables. Use the foundation counterplate (B

pic. # 3), with the 4 anchors supplied to be buried in concrete; or,

once the floor slab is completed, fix the cabinet to the barrier with

4 M10x120 foundation plugs (C pic. # 3). The slab thickness must

be at least 10cm and can be increased as required.

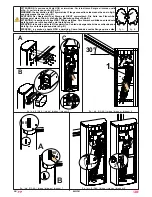

3.5_ Installation of the barrier group

Without bar and springs, the barrier must be positioned as follows:

- remove nuts and washers from the protruding bolts, position

the cabinet on the base and fix it. Check it is anchored securely

and correct if necessary.

Note: it is advisable to install the cabinet with the door on the side

more easily accessible.

- Open the door with the relative key and remove.

LUXE is normally delivered RIGHT (RH), with the bar support in a

horizontal

position.

Right-hand barriers (RH) are barriers that have

the cabinet on the right-hand side viewed from the inside of the

passageway (the door is normally on the inside). If it is necessary

for it to be LEFT (LH), the opening must be inverted.

Proceed as follows:

1_ after removing the eye screws and the circlips, take the pins

and reposition them, symmetrically, on the opposite side of the

drilled beam (pic. # 4A), fix with the circlips and screw the

screws in again;

2_ after removing the locking screw and washer, remove the bar

balancing lever. In the spring supporting group, invert the posi

-

tion of the pin (1 pic. # 4B), rotate the whole block by 180° (in

respect of the previous position) and fix the motor shaft again

with bolt and washer (pic. # 4C);

3_ once the opening direction has been modified, invert the motor

connections (see K206MA instructions).

The drilled beam allows to determine different maxi-

mum loads (in relation to the length of the bar and ac-

cessories applied) in the various positions (the nearer

to the vertical, the lower the maximum load).

Once the opening direction is modified, the positioning

of the devices must be inverted.

If the barrier must be modified from LH to RH, the operations are

the same.

3.6_ Bar fixing, spring fitting and bar balancing

All operations must be carried out with the power OFF.

After releasing the automation (see the “Manual release” chapter),

proceed as follows:

1_ using a support, bring the bar in the horizontal position (wholly

assembled and with all the accessories) near the bar support

and fix with the omega bracket and the screws supplied (pic. #

5A);

Note: the bar must be inserted for the whole length of the ome-

ga bracket.

2_ when the omega bracket is fixed, and after removing the pro

-

tective cap, pass the LED cable through the hole on the cabinet

(to take the cable to the control unit, refer to figure 9) then fit the

cover and secure it with the screws supplied (pic. # 5B);

3_ place the bar in a vertical position and block the gearmotor (see

the “Manual release” chapter).

Fit the springs hooking them to the eye screws and rotate manually

in the direction of the arrow for the first preload (pic. # 5C).

Continue with bar balancing.

Before balancing the bar check on the table on page 4

the chosen spring, accessories to be applied and dis-

tance are adequate. Correct balancing is vital for the

barrier to work properly.

This operation must be carried out only when the bar has

been installed permanently with all its accessories.

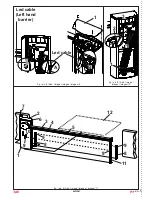

pic. # 6: operate the manual release (see the “Manual release”

chapter) keeping at a safe distance. The bar must move

to 30° on its own, if that is not the case load/unload the

springs (if the bar lifts above 30° the springs need to

be unloaded, that is they have to be rotated manually

in an anticlockwise direction, if it does not reach 30°,

the springs must be loaded, that is rotated manually in

a clockwise direction). Lower the bar and release it,

checking it has reached 30°.

For the barrier to work correctly, when loading/unload-

ing the springs, keep the same protrusion for the eye

screws (pic. # 5C).

Continue with the electrical connections to the control panel (see

the chapter on electrical connections).

Note: check the spring works correctly.

IMPORTANT! For a correct operation of the barrier,

when the boom is in vertical position the springs must

not be completely unloaded.

3.7_ Manual release

WARNING! Releasing and any other manual operation

must be carried out only with the bar fitted. It is abso-

lutely forbidden to operate the barrier without the bar

fitted.

1_ Insert the key into the handle lock on the back of the cabinet

and rotate by 180° in an anticlockwise direction (pic. # 7A);

2_ take the handle out and rotate by 90° in an anticlockwise direc

-

tion to release the bar (if it seems to resist, apply more strength

onto the handle since this will cause no breakage), pic. # 7B.

When released, the bar must automatically go to the balance

position (ca. 30°).

WARNING! Releasing can be potentially dangerous for

the user when for any reason whatsoever (bar badly

fitted during installation, bar broken due to an acci-

dent, etc.) the springs do not guarantee balancing any

longer!

They can cause the bar coupling and/or the bar itself to

rotate suddenly.

3.8_ Stop adjustment

The barrier is normally supplied with the stops already adjusted for

perfect travel.

If the plate has not been cemented properly, the bar might not be

perfectly horizontal or vertical and the installation might not be suc

-

cessful from an aesthetic point of view.

To correct the vertical position (=opening), close the bar, open the

door and rotate the free stopper (1 pic. # 8) in a clockwise (to in

-

crease the bar travel) or anticlockwise direction (to reduce the bar

travel).

Similarly, to correct the horizontal position (=closing), open the bar

and adjust the free stopper (2 pic. # 8).

After checking and adjusting the bar opening and closing opera

-

tion, tighten the locknuts under the stoppers.

Whenever the position of the mechanical stops is mod-

ified, the saving procedure on the control card must be

performed (see K206MA instructions).