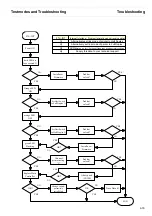

Testmodes and Troubleshooting

Display Message “Hardware Alarm”

4-25

5. Analysis

The Desired Position and the Actual Position should be identical or close together.

By moving the printhead the function of the horizontal timing belt can be tested (value

of Actual Position is changing). The value of the head clearance is always a desired

position since there is no response of actual head clearance. Default standard = 18;

AGA = rel. position; max. value = 131 (i.e. after Initializing resp. power on).

Please analyse Task Control Code using the table below.

6. Task Control Codes

Task Control Code Meaning / Description

1

Horizontal Task – active

2

Horizontal Task – Motor is accelerating

4

Horizontal Task – Motor Break on

8

Vertical Movement – active

16

Color Motor – active

32

Motor Function Select – active

64

Motor Sheetfeeder – active

128

Adjustment Printhead Clearance – active

128 B

Adjustment AGA

– shift the horizontal drive belt one notch to the right and fasten belt

again according adjustments 6.1.1 – active

256

Paper Feed Sheetfeeder – active

512

Bell (sound) – active

1024

Shiftmagnet Printhead – active

2048

Papermovement – active

4096

Tear / View from ESC Seq. – active

8192

Paper Load – active

16384

Paper Eject – active 32768 Tear or View (general) – active

The

Task Control Codes

may occur as combinations.

Example:

code 1026

Meaning:

Shiftmagnet inside the printhead active while the horizontal motor is accel-

erated.

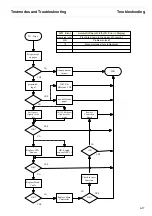

6.1 Hardware Alarm Task Code 1, 2, 3, 4 – horizontal task

Reason Solution

Printer stops intermittent in DRAFT

mode

Install newest firmware

Non Shielded interface cable according

IEEE 1284

Use a 2m max. shielded interface cable

IEEE 1284

Damaged or dirty timing strip

Clean*) or change strip

*) with a mild detergent

Head Adapter Cable

Mount new adapter cable

Defective logic

Install new main controller

Defective light barrier horizontal clock

– Clean intensive the contacts of the flat

cable from the light barrier – Change

light barrier

Noisy horizontal motor

Change CR motor

Summary of Contents for 2365

Page 1: ...Maintenance manual Matrix printer 2365 2380...

Page 2: ...This page intentionally left blank...

Page 8: ...This page intentionally left blank...

Page 10: ...This page intentionally left blank...

Page 20: ...This page intentionally left blank...

Page 32: ...Mechanical Functions Functional Description 3 12 right mark mark mark...

Page 35: ...Functional Description Electronic Functions 3 15 2365 2380 Electronic groups...

Page 128: ...This page intentionally left blank...

Page 134: ...Mechanical Adjustments Adjustments 6 6...

Page 136: ...Electrical Adjustments Adjustments 6 8...

Page 142: ...Housing Spare Parts and Schematics 7 2 7 1 Housing 7 1 1...

Page 144: ...Basic Printer Spare Parts and Schematics 7 4 7 2 1 Basic Printer 1 3 36...

Page 145: ...Spare Parts and Schematics Basic Printer 7 5 Basic Printer 2 3 462646...

Page 146: ...Basic Printer Spare Parts and Schematics 7 6 Basic Printer 3 3...

Page 151: ...This page intentionally left blank...

Page 164: ...Option Recognition Spare Parts and Schematics 7 24 7 10 Option Recognition...

Page 168: ...This page intentionally left blank...

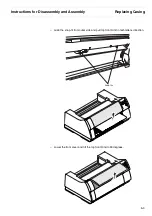

Page 170: ...Tractor Complete Rear Tractor 2T Model 8 2 8 2 Tractor Complete 4 1...

Page 172: ...This page intentionally left blank...

Page 174: ...Cutting Device Option Specifications 9 2 14 6 4 12 1 5 6 11 7 13 7 8 17 2 9 3 16 15 4...

Page 176: ...This page intentionally left blank...

Page 177: ...2nd Front Tractor option 10 1 10 2nd Front Tractor option...

Page 179: ...Printer Stand Overview 11 1 11 Printer Stand 11 1 Overview...

Page 180: ...Installing the Printer Stand Printer Stand 11 2 11 2 Installing the Printer Stand 1 2 3 4...

Page 181: ...Printer Stand Installing the Printer Stand 11 3 6 8 7 5...

Page 182: ...Installing the Printer Stand Printer Stand 11 4 9 10...