20

|

20

function LOGIC

(only with machines PROCESSOR and SyNERGIC)

Function lOGIC includes a file of simplifying and clarifying points which pre

-

sent adjusted and currently set values.

If two displays show a few different parameters, it is necessary to simplify

presentation of parameters. Function lOGIC operates just in this way - it

makes everything clear and distinct:

• Upper display switches on during welding process only when electronics

makes measurements and shows welding current A (in case there is no

mode SyNERGIC on. In case there is mode SyNERGIC on display is lit up

constantly and only shown values change). After approx. 7 sec. display

switches off automatically again. Thus electronics increases orientation

while reading parameters during adjustment.

• Upper display shows only welding current. When function SyNERGIC is

on (only with machines Synergic), upper display shows thickness of mate

-

rial.

• bottom display shows welding voltage while welding and other values -

time, speed etc. during adjustment.

• lED SETTING will switch off during welding process only when a digital

voltampermeter is used.

• lED SETTING is on during welding only when operating staff is adjusting

and changing speed of wire shift with a potentiometer or a remote con

-

trol UP/DOWN. As soon as operating staff stops adjustment of a para

-

meter, lED SETTING will be switched off automatically within 3 sec. and

display shows value of welding voltage.

Recommended adjustment of welding parameters see charts on pg. 23 - 29.

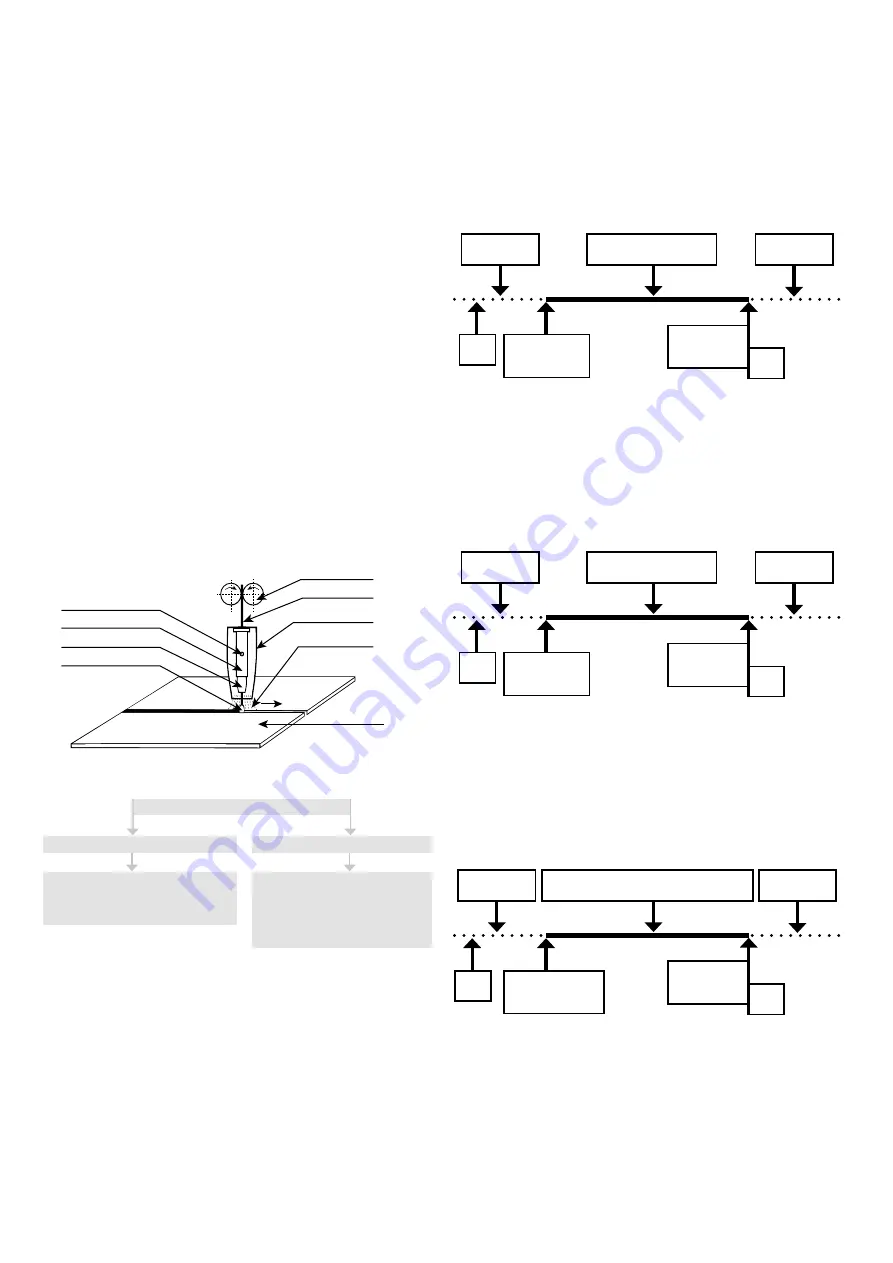

Principle of mIG/mAG welding

Welding wire is lead from the roller into the flow drawing tie with the use of

the feed. Arc joins thawing wire electrode with welding material. Welding

wire functions as a carrier of the arc and as the source of additional material

at the same time. Protective gas flows from the spacer which protects arc

and the whole weld against the effects of surrounding atmosphere (pic. 6).

Gas opening

Tip holder

Welding tip

Welding arc

Wire feeder rolls

Welding wire

Nas nosle

Protection gas

Welding

piece

Picture 6

Protection gases

Protective gases

inert gases - Mig method

Active gases - Mig method

Argon (Ar)

Helium (He)

Mixtures of He/Ar

carbon dioxide

Mixed gases

Ar/cO

2

Ar/O

2

Principle of setting welding parameters

Guidance for setting welding current and voltage MIG / MAG corresponds to

the empirical relationship U

2

= 14 + 0.05 x I2. According to this relationship,

we can determine the necessary tension. When setting the voltage, it must be

taken into account when it falls under the welding load. The voltage drop is

about 4.8 V per 100 A.

The welding current is adjusted by adjusting the required welding current

for the selected welding voltage by increasing or decreasing the wire feeding

speed, or by fine-tuning the voltage until the welding arc is stable. To achie

-

ve a good weld quality and optimum welding current setting, the distance

between the feed die and the material must be approximately 10 x Ø of the

welding wire (pic. 6). Drowning the die in the gas nozzle should not exceed

2 - 3 mm.

Welding work cycles

Welding machines work in four working cycles:

• continuous two-stroke time

• continuous four-stroke time

• spot welding two-stroke time

• pulse welding two/four -stroke time

Two-stroke cycle

Welding process is started by only the pressing the switch of the torch. The

switch must always be held during the welding process and it can be inter

-

rupted releasing the switch of the torch.

PRE-GAS

WElDING PROCESS

POST-GAS

END OF THE

WElDING

PROCESS

START OF THE

WElDING

PROCESS

1

2

1 - Push and hold the switch of torch

2 - Release the switch of torch

four-stroke cycle

It is used to weld long, when the welder does not have to hold the switch of

the torch all the time. you will start the welding process in such a way. After

releasing of the switch, the welding process still goes on. Only after a fur

-

ther pressing and releasing of the switch of the torch, the welding process

is interrupted.

PRE-GAS

WElDING PROCESS

POST-GAS

END OF THE

WElDING

PROCESS

START OF THE

WElDING

PROCESS

1-2

3-4

1-2 Push and hold the switch of torch

3-4 Release the switch of torch

Spot welding

It is used for welding by individual short spots, whose length can be con

-

tinuously adjusted for required value. by pressing the switch on the torch,

the time circuit is started, which starts the welding process and after the

set time it turns off. After further pressing the button, the whole process is

repeated.

PRE-GAS

WElDING IN ADJUSTED TIME

POST-GAS

START OF THE

WElDING

PROCESS

1

END OF

THE WElDING

PROCESS

2

1 - Push and hold the switch of torch

2 - Release the switch of torch

EN