7

VAR

Swegon reserves the right to alter specifications.

20111011 www.swegon.com

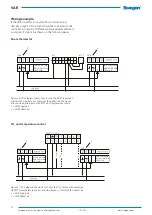

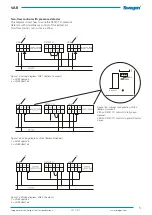

Jumper connection - RTC

The jumper connection in the RTC must be changed

when you wire the thermo-actuator (3) to the system. See

the figures below. A maximum of 4 thermo-actuators are

permitted to be wired to the same output.

N.B.! The unit must be de-energized before you recon-

nect any jumpers!

More information on the RTC can be read in its Installa-

tion – Commissioning Instructions.

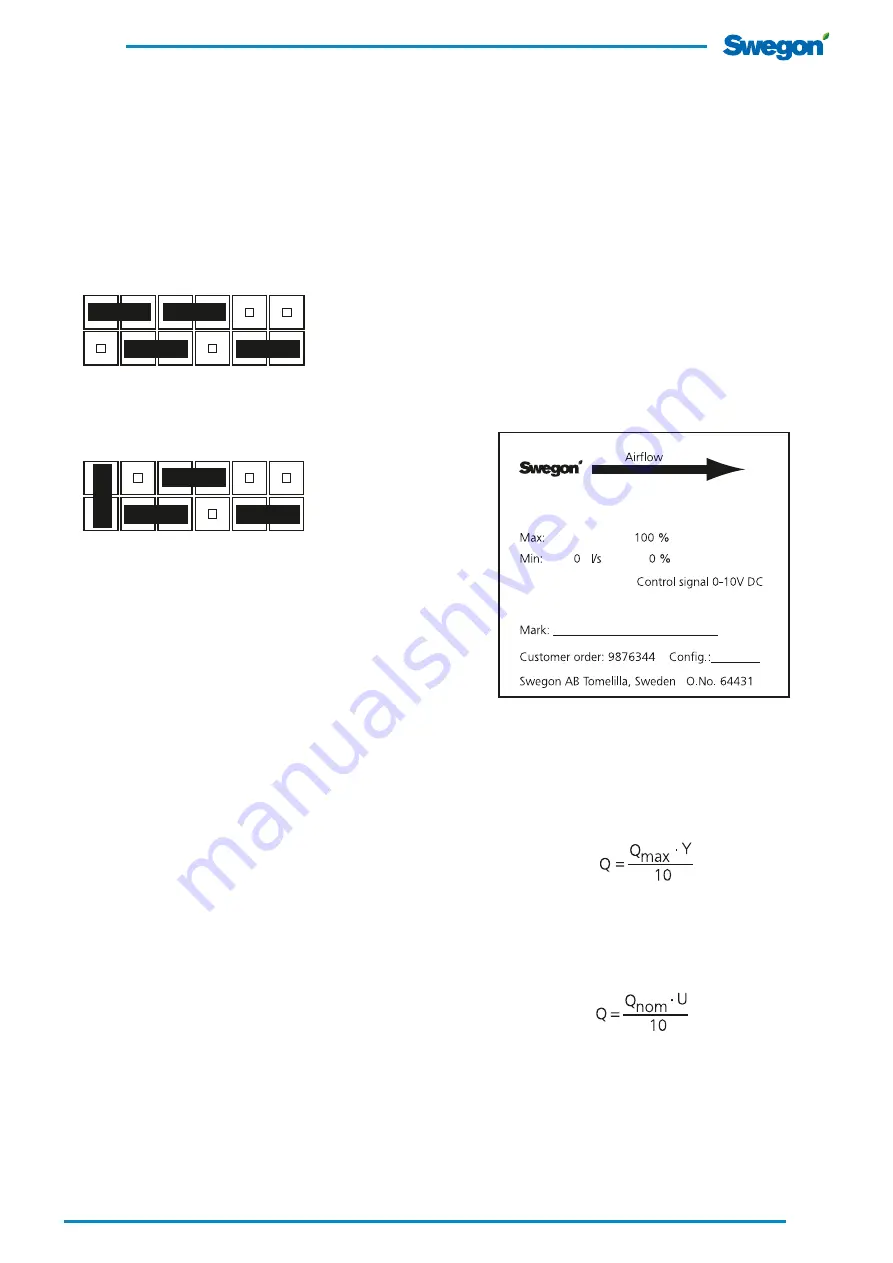

Figure 19. Jumper connection for thermo-actuator, heat.

YK = Cooling energy regulation: 0-10V DC

YH = Heat regulation: 024V DC

Figure 18. Jumper connection, Delivery settings.

YK = Cooling energy regulation: 0-10V DC

YH = Heat regulation: 0-10V DC

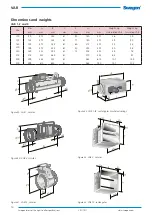

Nom flow = 170 l/s

VARd 1-160

k-factor = 15,5

170 l/s

Commissioning - Flows

General points for all types

The VAR variable-flow commissioning dampers are

factory-calibrated and are normally preset for the airflow

range specified for the project. The setting values can be

read on the product rating plate affixed on both sides of

the product. Installation info and electrical connections

are described in these instructions. For the best perfor-

mance, it is extremely important that the requirement

for lengths of straight duct upstream or downstream of

the VAR is complied with. If you arrange only half of the

required length of straight duct, this may increase the

control tolerance from 5 up to 20%. The airflow direction

should always be such that the damper is fitted down-

stream of the flow measuring device. The unit’s rating

plate includes air direction arrows.

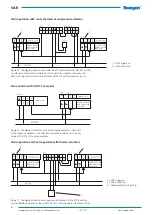

Control signals

All the electronic VAR devices are designed for a signal

range of 0-10V DC. Any deviation from this range is

indicated on the product rating plate. If a direct-wired

room thermostat is used for controlling the airflow

requirements, then a control voltage of <0.5V implies the

min. airflow that is preset in the controller and 10 V then

produces the max. airflow. It is common that the control

is carried out via a controller that then manages the min./

max. airflow setting by limiting the control signal e.g.

from 2.3 – 7.6 Volt DC. If wired to a controller, the VAR is

normally set to 0-100% of its operating range. N.B. In some

cases, high airflows can generate increased sound levels.

Figure 20. Shows the product rating plate.

Formulas for calculating airflows.

Formula 1, where Q = l/s and Y = control voltage.

Formula 2, where Q = l/s and U = true value voltage.

If the true value signal is used, the airflow should be

worked out with Q

nom.

Airflows

The VAR has a nominal air flow, Q

nom

for each size.

The maximum air flow can be set to between 30 and

100% of Q

nom

.

The minimum air flow can be adjusted in relation to Q

nom

and can be set to between 0 and 100% of Q

nom

.

The regulators cannot manage air flows less than Q

min

,

as the manometer reading then becomes too low and

regulation ceases.

VAR 1, 2 and 4 can be supplied in special versions with

larger max. flow, up to 200 Pa read on the manometer.

The consequence of this is less accuracy in the lower range.