11

VAR

Swegon reserves the right to alter specifications.

20111011 www.swegon.com

3,52 V

V DC

-

+

PP

Z1 Z2

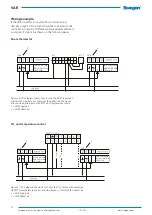

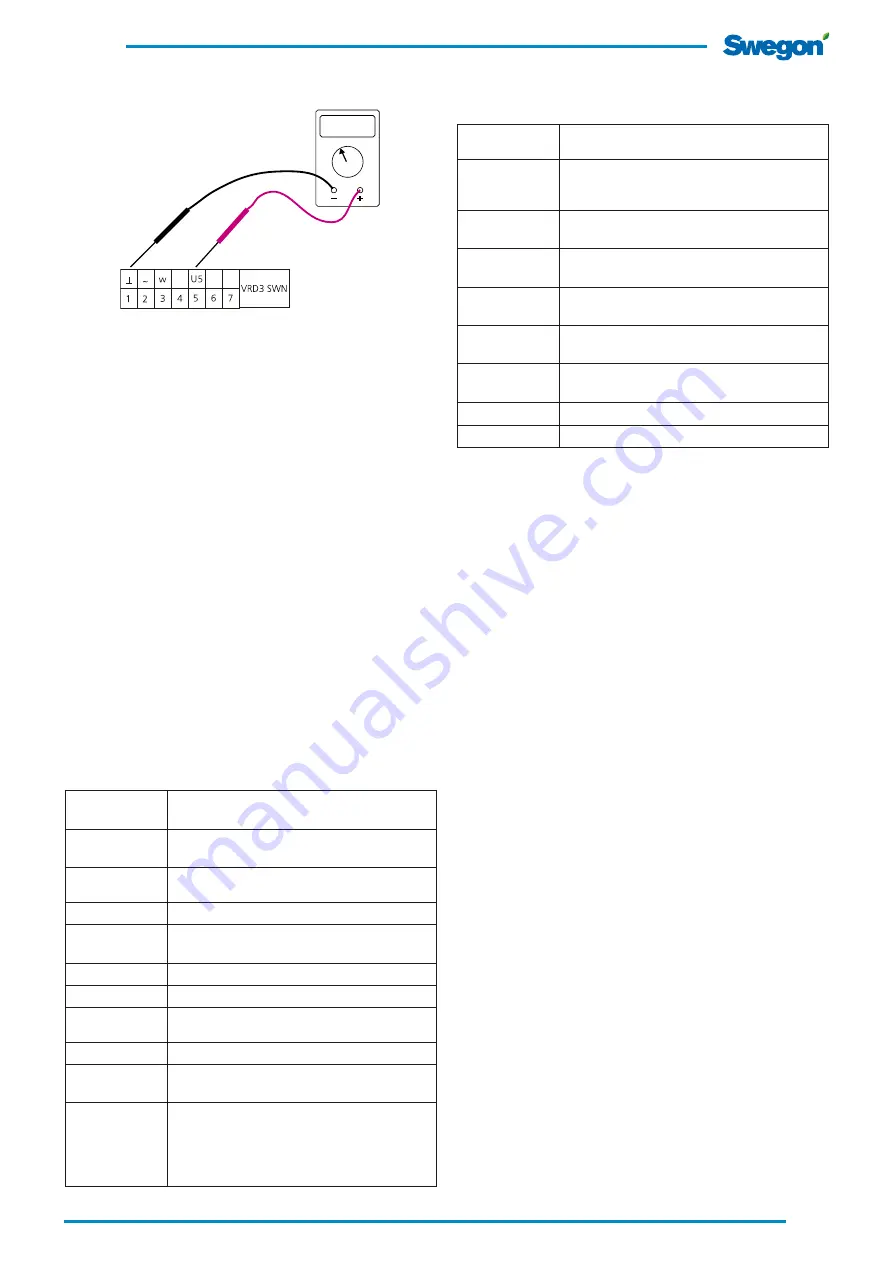

Figure 23. Shows how to connect a voltmeter for checking the

true value.

Trouble shooting

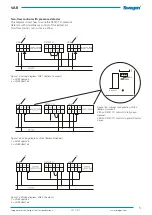

Incorrect polarity on control signal zero conductor

It is important that the neutral conductor follows the

entire chain of connections from thermostat to control-

ler. Check this by measuring the control voltage between

cables 1 and 3 on the VAR. Correctly wired it should be

possible to vary the signal between 0.5-10 V DC. If incor-

rectly wired the signal will be ~ 8 - 14 V DC; for the RTC

the signal will be ~ 2 - 8 V DC.

The airflow does not agree

This is almost always due to that the requirements for

lengths of straight ducting upstream/downstream of the

VAR have not been met. If the ducting deviates from these

requirements, the error can be as much as 20%. The flow

measurement sensor may become fouled in systems with

considerable dusty air (most often extract air systems). This

however doesn’t occur until the system has been operating

for 3-5 years. The sensor can be cleaned by blowing it with

clean air in the opposite direction, i.e. in the tube connec-

tion. We recommend compressed air in a low-pressure

aerosol tube. The duct must also be cleaned so that the

measurement flange and the pressure tappings are not

clogged.

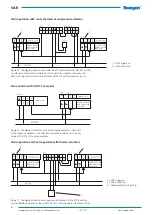

Changing the settings

The min./max. airflow values are calculated and set as

follows:

Q

max

% required max. airflow (Q

max

) divided by nominal airflow

(Q

nom

).

Q

min

% required min. airflow (Q

min

) divided by nominal airflow

(Q

nom

).

Example:

VAR, dim. Ø160, required min./max. airflows: 51/119 l/s.

Q

max

% = Q

max

/ Q

nom

=>119/170 = 0.70 = 70%

Q

min

% = Q

min

/ Q

nom

=> 51/170 = 0.30 = 30%

Q

nom

is read from Table 1 on page 9.

Enter the settings directly in the controller. No external

instrument is needed but the settings can also be adjusted

with Belimo’s instrument, ZTH-GEN.

Configuration menu ZTH-GEN

Start:

Hold the (OK) button depressed and at the

same time connect to the VAV controller.

HW Version

SW Version

Indicates which hardware or software ver-

sion the unit runs

Reply:

"Configuration menu"appears in the display

window

Select setting

Press the

▼

button (see selection below)

Choice of

language

German

*

/English

Choice of unit

m

3

/h

*, l/s, cfm

Voltage

DC/AC 24 V (shows current supply voltage)

MP test

Shows the pulse train in the network (for

system integrator)

Expert mode

0 */ 1 (provides expanded access to settings)

Advanced

mode

0 */ 1 (provides expanded access to settings)

Exit

Via menu selection (returns automatically to

the mode for configuring the VAV controller)

or for removing the connection to the VAV

controller. The selected settings are automa-

tically stored in the ZTH.

Start menu of the VAV controller

VRD3 SWN

Indicates to which controller the ZTH-GEN is

connected.

Volume 0%

Setpoint 0%

Shows the true value in % of the nominal fl

ow Shows the calculated

set point

Volume 0%

Pressure 0Pa

Shows the true value in % of the nominal flow

Shows the manometer pressure in Pa

Volume 0%

CAV-Step

Shows the true value as a percentage of the

nominal

Auto

, Open, Close, Vmax, Vmin, Stop

Mode 0.0-10.0

-new:

Shows the current operating range for control

signalRange for control signal 0-10V or 2-10 V

Vmin

-new

Set point for min. flow in %

Set point (potentiometer in tool area)

Vmax

-new

Set point for max. flow in %

Set point (potentiometer in tool area)

Vnom

Shows nominal flow in %

p@Vnom

Shows nominal flow in Pa