396

-

3815Y1 SureFire PumpRight for Raven RCM

54

Revised 12/04/2019

1.

Be sure the Pressure Sensor that is displayed on your screen is the same sensor that is plugged into your harness

for that product (Sensor 1 or Sensor 2).

2.

Make sure the pins where the harness screws on to the end of the sensor have not been bent.

3.

Be sure Pressure Sensor is set up and calibrated in the display. Unplug the pressure harness before doing this.

S

etup > Settings > Pressure Sensor Setup. Select the sensor you want. > Calibrate Pressure Sensor >

Voltage

-

based Calibration > 50 mv/PSI.

4.

There should be a green LED light on the end of the pressure sensor. This may be difficult to see in daylight. The

sensor needs 12 v. Check between pins B&C on the Pressure connector on the harness that connects to the

pressure sensor. If there is no voltage here, check the voltage between pins 1 & 2 on the 12

-

pin connector labeled

PUMP.

5.

Testing Pressure Sensor Harnessing:

If the pressure sensor is not reading, you can use a AA or AAA battery to

test the harnessing. Connect the (

-

) end of the battery to pin C and the (+) end to pin A of the pressure connector.

The 1.5 v should show up as 30 psi on the screen. You can check this at

Diagnostics > System Information >

Pressure Sensors

. (0 PSI should be 0.0v)

Pressure Sensor is not reading

Section Valve(s) will not move

1.

Go to

Diagnostics

> Tests > Control/Section Test

to investigate this issue. If system shuts off with Solution Pump

Dry warning, use the Calibrate PWM Limits Test.

2.

Start Section Test. Check and uncheck the boxes. With the box checked the valve should turn on. The valve should

be off with the box not checked.

3.

If none of the valves are working, or if half of the valves are working, it may be a Power (or Ground) issue. The odd

-

numbered sections have one power source, the even

-

numbered sections have another power source. (See harness

diagrams)

4.

If a valve does not open, switch the connector that is plugged into that valve with a con-

nector that is plugged into a working valve. Also, plug in the connector to the non

-

working

valve to a valve that is working.

5.

Check the harness connection to the non

-

working valve. It is a 3

-

Pin Weather Pack con-

nector. Check voltage pin A to Pin B. Must be 12 volts, if not, go back to the next harness

connection and check the voltage there. (See harness diagrams for pins)

6.

If voltage is present on pins A&B of 3 pin connection to valve, then check Pin C to Pin B. This should be 12 volts

when the valve is commanded on or open. This should be zero volts when valve is off or closed.

7.

If signal voltage is not present to open valve, use diagrams to check at the 14

-

pin connector, then the 47

-

pin for volt-

age on the proper pin for that section.

8.

If harnesses and voltages are good, but valve still will not open, remove the actuator from the valve and see if the

actuator will work when it is not connected to the valve. Use a wrench to turn the valve to be sure it is moving freely.

Be sure actuator and valve are oriented correctly when you put them back together.

9.

If constant voltage (Pins A&B) and switched voltage (Pins C&B) are present, inspect, repair or replace the valve.

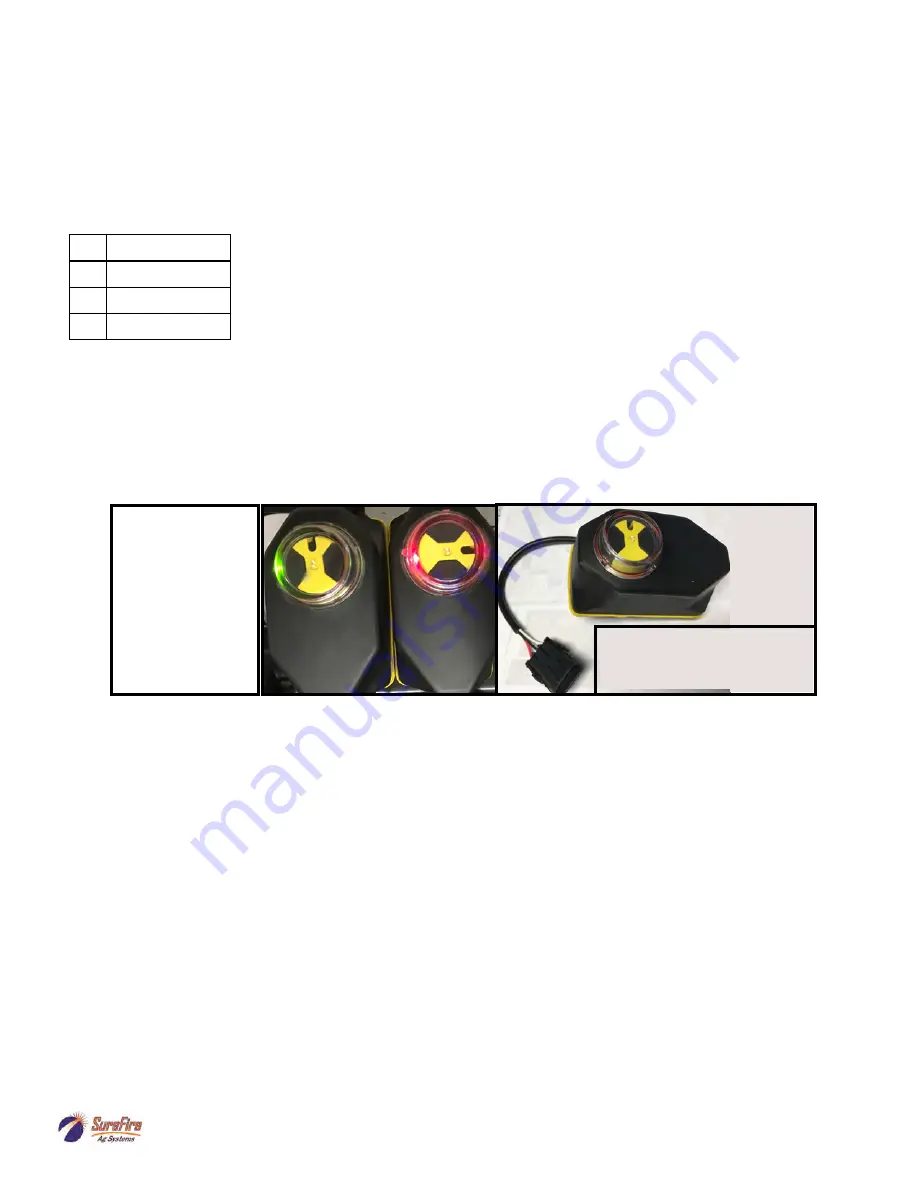

Pin

Function

A

+ 12 V Constant

B

Ground

C

+ 12 V Signal

Green Light-

Valve ON

Red Light

Valve OFF–

connected to

Power

If valve indicator

stays GREEN all

the time or if valve

indicator is not in

full ON or full OFF

position, replace

actuator. Pull gray

pin to remove actu-

ator from valve.

Replacement Valve Actuator—

104

-

KZ1169

—KZ Electric

TX2 Series Actuator

This is a 3

-

way valve

. If product will not flow when valve is ON, either move the outlet hose to the other

outlet port, or remove actuator and rotate valve ball 180º, and replace actuator. Product should flow

through the port closest to the Indicator light when the valve is open (green).

SureFire

Ag

Systems