HSC86AInstruction manual of hybrid servo driver

11

requirements, the shielded wire of the control signal cable is grounded at one end: the upper end of the

shielded wire is grounded and the shielded wire End of the drive is floating. The same machine is only

allowed to be grounded at the same point. If it is not a real ground wire, the interference may be serious.

At this time, the shielding layer is not connected. If the conditions permit, thermal grounding

technology is most effective for shielding.

2) The pulse and direction signal lines and the motor line are not allowed to be bundled side by side,

preferably separated by at least 10cm or more, otherwise the motor noise will easily interfere with the

pulse direction signal and cause motor positioning inaccuracy, system instability and other faults.

3) If one power supply is used for multiple drives, parallel connection should be adopted at the power

supply, and it is not allowed to go to one first and then to another chain connection.

4) It is strictly forbidden to plug and unplug the driver terminal with el ectricity. When the live motor

stops, a large current still flows through the coil. Pulling and plugging the terminal will cause a huge

instantaneous induced electromotive force to burn the driver.

5) It is strictly forbidden to insert the wire head into the terminal after tin, otherwise the terminal may

be damaged due to overheating of the contact resistance.

6) The wiring head should not be exposed outside the terminal to prevent accidental short circuit and

damage to the driver.

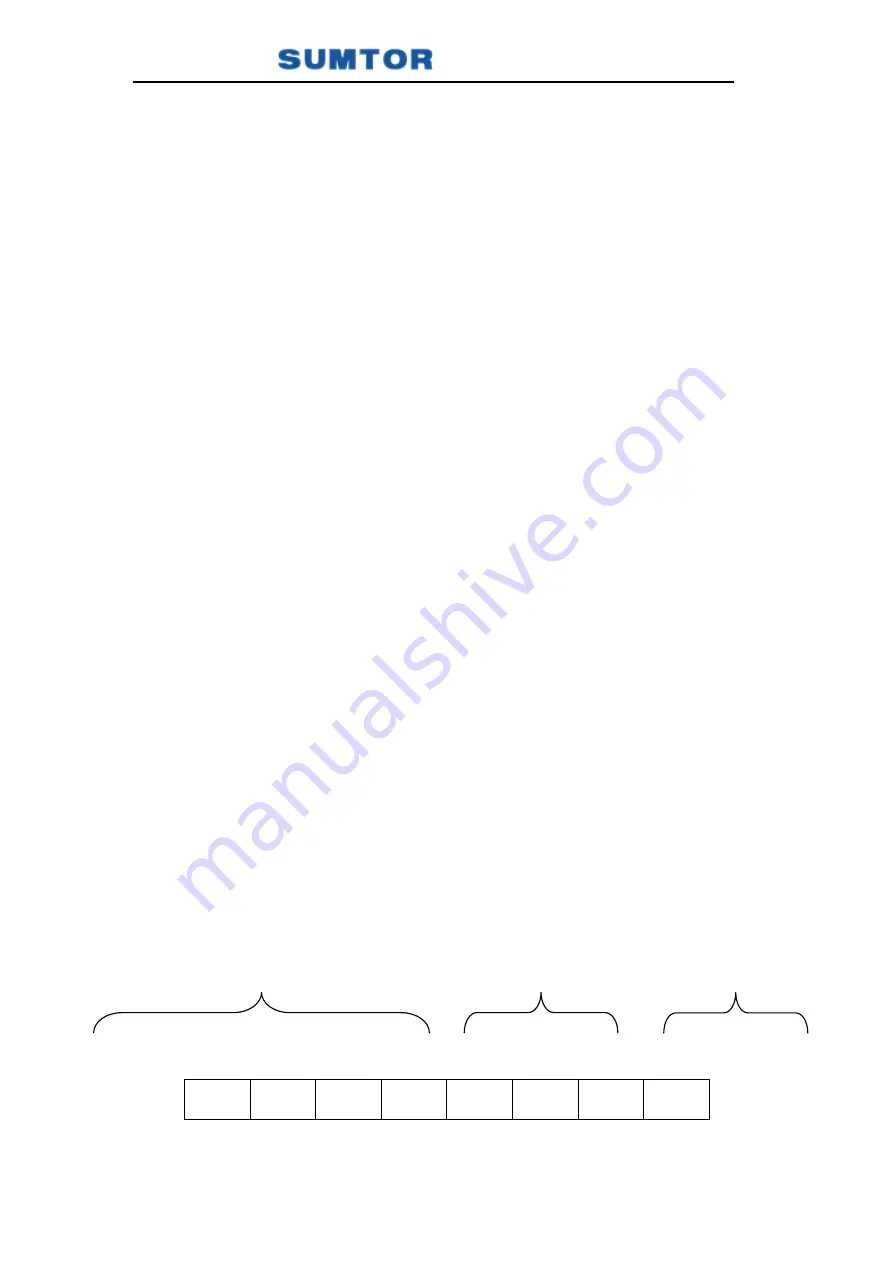

四、DIP switch setting

HSC86A digital integrated low-voltage servo driver adopts 8-bit dial switch to

set the subdivision accuracy (electronic gear ratio), the initial direction of

motor rotation, self-test and function mode selection. The detailed description

is as follows

:

SW1

SW2

SW3

SW4

SW5

SW6

SW7

SW8

Direction and function mode settings

Subdivision accuracy (electronic gear ratio)

Motor selection