4

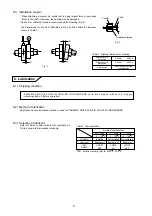

4-2 Installation of gear box

The mounting base must be horizontal and level.

4-1) Location of installation

Ambient temperature

: 0 to +40

(+32 to +104

Ambient humidity

: 85% max.

Ambient atmosphere

: There shall be no corrosive gas, explosive gas.

The installation space shall be well ventilated, and free from dust.

Location of installation : Indoors or outdoors.

. Special specifications are necessary when installation conditions are other than those mentioned here.

In such cases contact the nearest agent, dealer or service office.

. When a product is made according to special specifications for outdoor use or use in explosive

environments, the product can be safely operated under those specified conditions without problem.

(Air vent or air breather must be located outside of fan stack with extended piping)

Table1 Torque of the installation bolts

Unit

SFC060

SFC065

SFC070

SFC075

Bolt Size

−

M30

M36

Torque

N

・

m

1400

2430

Size

in

・lbs

12390

21510

. Install PARAMAX DRIVE FOR AIR COOLED CONDENSERS on a sufficiently rigid base.

. Use installation bolts corresponding to JIS strength class 8.8 or its equivalent. The torque of installation bolts is

shown in table1.

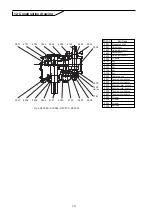

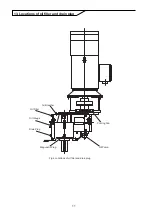

5. Coupling with other machines

CAUTION

Install appropriate guard devices around rotating parts ; otherwise, injury may result.

Correctly tighten respective bolts to the specified torque shown in the drawing, catalog, etc. ; otherwise ;

scattering fragments may damage the system.

IF a backstop is installed in the reducer, verify that the applied motor rotation direction is correct.

Difference in the direction of rotation may cause injury or damage to the system.

C

C

F)

F

When coupling PARAMAX DRIVE FOR AIR COOLED CONDENSERS with a load, confirm that the alignment

error is within the specified limits shown in the maintenance manual, drawings, catalog, etc. ; otherwise,

damage to the system may result, due to misalignment.

Remove the key temporarily attached to the output shaft of PARAMAX DRIVE FOR A I R C O O L E D

CONDENSERS when the shaft is free-rotating (i. e. not loaded) ; otherwise, injury may result.

Summary of Contents for PARAMAX SFC Series

Page 14: ...GM2202E 1 0 2004 2...