1

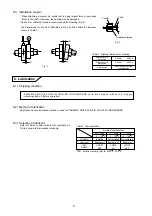

Matters described in may lead to serious danger depending on the situation. Be sure to observe

important matters described herein.

DANGER

Transport, installation, plumbing, operation, maintenance, and inspections should be handled by properly

trained technicians ; otherwise, injury or damage to the machine may result.

Do not disassemble PARAMAX Drives FOR AIR COOLED CONDENSERS during operation. Even if it is at

disassemble any parts other than the oil inlet/outlet when the input/output shafts of the PARAMAX

DRIVE FOR AIR COOLED CONDENSERS is connected to a motor or other mating machines; otherwise falling

or operation out of control due to disengagement of gears, as well as death, injury, or damage to the machine may

result.

Carefully read this maintenance manual and all accompanying documents before use (installation, operation,

maintenance, inspection, etc.). Thoroughly understand the machine, information about safety, and all precautions for

correct operation.

Maintain this manual for future reference.

Pay particular attention to the "DANGER" and "CAUTION" warnings regarding safety and proper use.

DANGER

CAUTION

The unit should be operated only within its design and performance specifications ; otherwise, injury or

damage to a system may occur.

Keep hands and all foreign objects from the internal moving parts of the unit ; otherwise, injury or damage to

a system may occur.

Damaged units should be taken off - line and not put back in operation until properly repaired.

Any modifications or alterations of any kind, to the unit, will void the warranty and all subsequent claims.

Do not remove the rating plate.

CAUTION

CAUTION

CONTENTS

Safety and other precautions.......................1

1. Inspection upon delivery ............................ 2

2. Storage....................................................... 3

3. Transport .....................................................3

4. Installation .................................................. 3

5. Coupling with other machines .................... 4

6. Lubrication.................................................. 5

7. Backstop..................................................... 6

8. Operation ................................................... 7

9. Daily inspection and maintenance ............. 8

10. Troubleshooting ......................................... 9

11. Disassembly/reassembly and disposal ...... 9

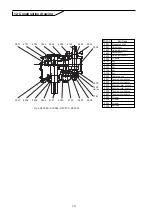

12. Construction drawing ............................... 10

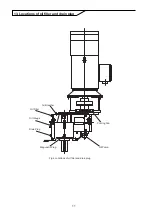

13. Locations of oil filler and drain plug ...........11

14. Warranty................................................... 12

Oil has been removed from PARAMAX DRIVE FOR

AIR COOLED CONDENSERS

before shipment from our

factory, so supply recommended oil before use.

: Improper handling may result in physical damage, serious personal injury and/or

death.

: Improper handling may result in physical damage and/or personal injury.

(Safety and other precautions)

rest, do not

Summary of Contents for PARAMAX SFC Series

Page 14: ...GM2202E 1 0 2004 2...